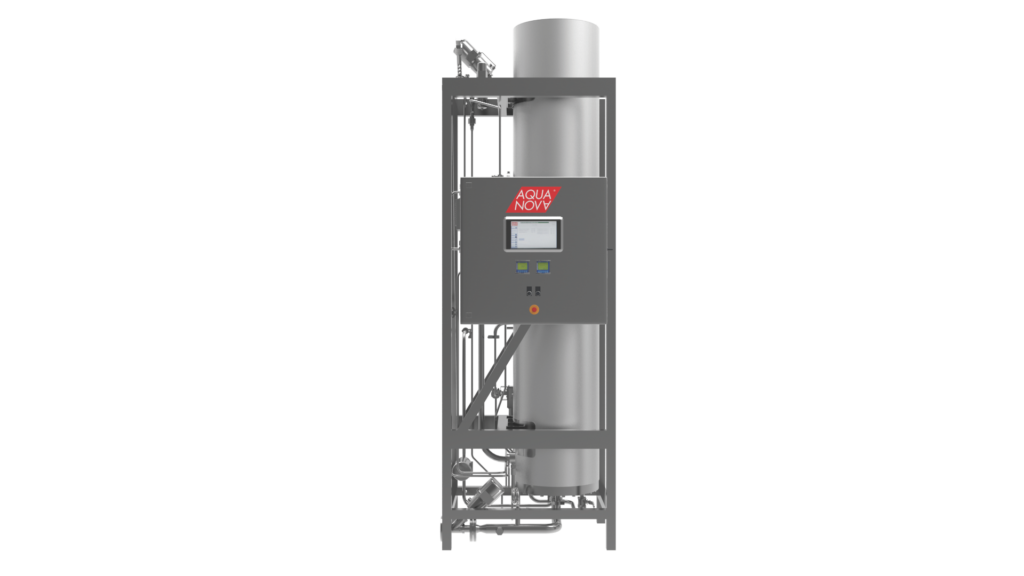

Aqua-Nova represents the 3rd generation of Multi-effect WFI Water Still and Pure Steam Generators where proven, reliable technique and modern design are combined in an efficient way.

Our original design from 1981, with ‘float’ type heat exchangers and low steam velocities combined with cyclone separation and proportional media regulation, is still the most reliable way of producing Water For Injection (WFI) and Pure Steam (PS) as per the latest, international pharmacopoeias.

.

System Operation

AQUA-NOVA Pure Steam Generators operates in the same way as the 1st column of a multi-effect still. All feed water is normally heated to a minimum temperature >143 °C. The PS Generator operation is self-regulating even at pressure variations in heating steam and feed water and adjusts automatically to the consumption variations, needing no feed water tank.

All units are inspected and approved by the pressure vessel authorities, according to the relevant pressure vessel code.

Product Specification

Our ‘float’ type heat exchangers are fully submerged in the water thereby avoiding thermal stress, which can originate micro cracks in the material. The tubes and the mantle work under the same conditions of steam & water whereby contraction and expansion is absolutely uniform.

Sebastian Bjorksten

Managing Director Sofinn UK Ltd

“We will work with your team to select the best products and specifications that meet your needs. We can handle everything from your first phone call to the installation.”

Call: +44 7539 432 772

Email: sebastian.bjorksten@sofinn.com

Pure Steam Generators

Our 3rd Generation Pure Steam Units deliver Pure Steam of WFI (Water For Injection) quality, meticulously designed to meet the stringent guidelines set forth by the latest editions of USP and EP. Engineered for optimal performance and safety, these units come with a fully automatic function and surveillance system. A unique 4-step separation mechanism ensures maximal operational safety and high flexibility. Additionally, the units offer Pure Steam quality sampling and feed water degassing features. Designed to be space-saving and easy to install, these units represent the pinnacle of streamlined, efficient technology for the pharmaceutical industry.

| Product Name | Plant Steam Pressure barg g | Capacity Kg/h |

|---|---|---|

| SG-200-1 | 2-3 | 60-120 |

| SG-300-1 | 2-3 | 120-240 |

| SG-400-1 | 2-3 | 400-540 |

| SG-500-1 | 2-3 | 750-1000 |

| SG-600-1 | 2-3 | 900-1600 |

| SG-700-1 | 2-3 | 1400-2100 |

| SG-1200-1 | 2-3 | 2800-5000 |

EXAMPLE OF OPTIONAL EQUIPMENT

- Feed water degassing.

- Pure Steam sample condenser with conductivity registration.

- Sterile air vent filter and close off.

- Heat steam safety relief valve & pressure shut off.

- Electro polished internal surfaces.

- Boroscope inspection of internal welds.

- Central control cabinet for the complete PS system.

- Pure Steam pipe systems.