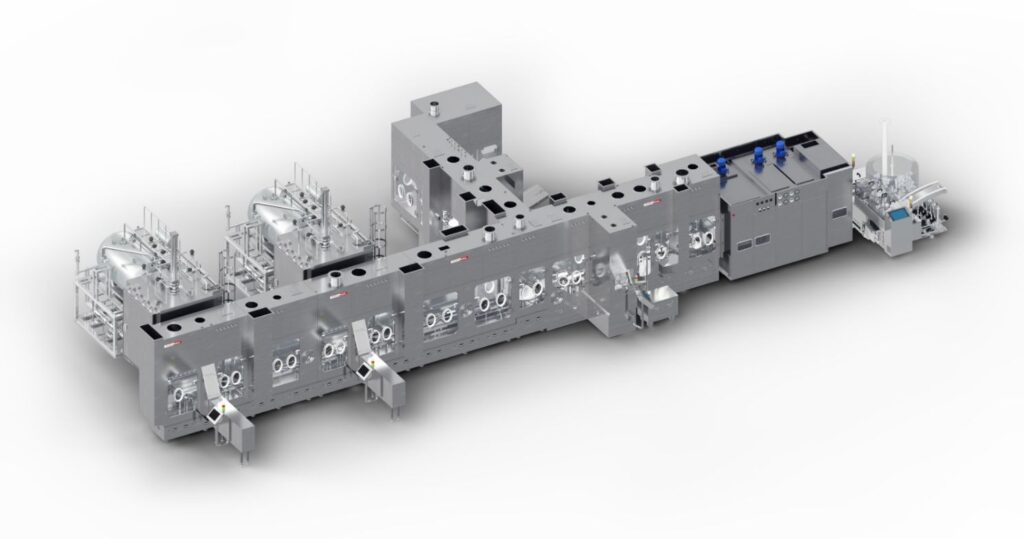

Aqua-Nova COMBI unit – Two in One

WFI and Pure Steam: two similar and yet different fluids

Simultaneous production is possible thanks to the unique Aqua-Nova technology. Here’s how!

Following strong interest

We are:

Committed to quality: We take pride in our unwavering commitment to delivering top-end solutions.

Service quality: We are dedicated to providing exceptional service. Your satisfaction is our measure of success.

Making complex projects smooth: We specialise in simplifying the most intricate projects.

Project delivery made easy: We make project delivery as easy as possible, ensuring you get what you need when you need it.

The Supplier who listens to the customer’s needs: We don’t just provide solutions; we understand your unique requirements and tailor our offerings to match your specific application.

Match your application with the correct technology: Our in-depth knowledge allows us to match your project with the most suitable technology.

Machine suppliers: As a leading supplier of sterilisation equipment, we are for cutting-edge machinery.

Appreciation of customer relationship: We believe in the power of personal initiative and building lasting relationships.

The Sofinn Group, with its network of fully or partially owned sister companies, emphasises proximity and local service as core pillars of its business model. Our diverse presence across various countries allows us to maintain a unique balance of international reach with a localized touch. By prioritizing customer-centric service, we ensure that we are always within reach, providing tailored solutions right where our clients need them most.

Our manufacturing operations, rooted in Sweden and France, are testament to this philosophy. Here, we produce a range of specialised products including WFI stills, PSGs, and effluent decontamination stations, all complemented by custom-designed loops. This setup not only demonstrates our commitment to quality and innovation but also reinforces our ability to offer local, responsive service to our international clientele.

+ 44 1633 415 355

info@sofinn.com

Address:

S16 Gold Tops, Newport, Gwent, NP20 4PH, United Kingdom

+ 44 1633 415 355

info@sofinn.com

Address:

Sofinn SA, 15 bis rue de Tourville78100 Saint Germain en Laye, France

+ 44 1633 415 355

info@sofinn.com

Address:

Lee View House, South Terrace, Cork, Co. Cork, Cork T12 T0CT

+ 33 6 45 77 38 96

fr@sofinn.com

Address:

545 Allée du Sous Maillé Ecoparc 2

27400 Heudebouville, France

+ 44 1633 415 355

info@sofinn.com

Address:

Stridsvagnsvägen 14, 291 39 Kristianstad, Sweden

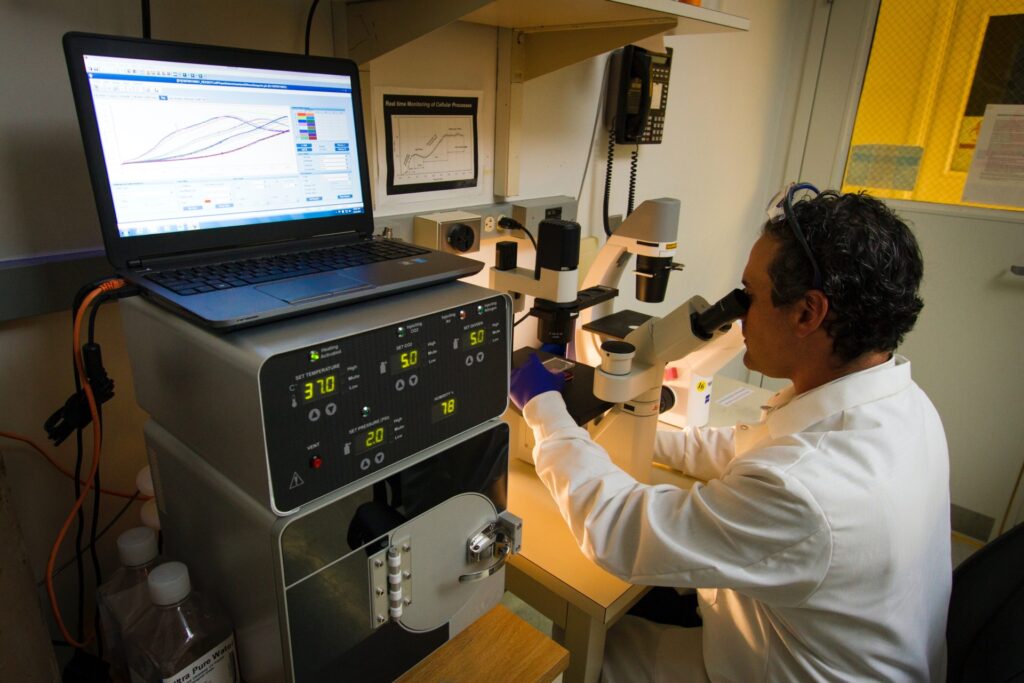

Our wide product range varies from WFI & Pure Steam solutions, feedwater and distribution loops and effeluent Decontamination stations in various sizes build in our factory in France the Aqua-Nova facilities in Sweden. Our long standing partnership with Lytzen in several countries in Europe has given as an unparalleled expertise in dry heat sterilisation and drying. The Tofflon Lyophilisation and filling lines represent state of the art equipment. We excel in sterile applications.

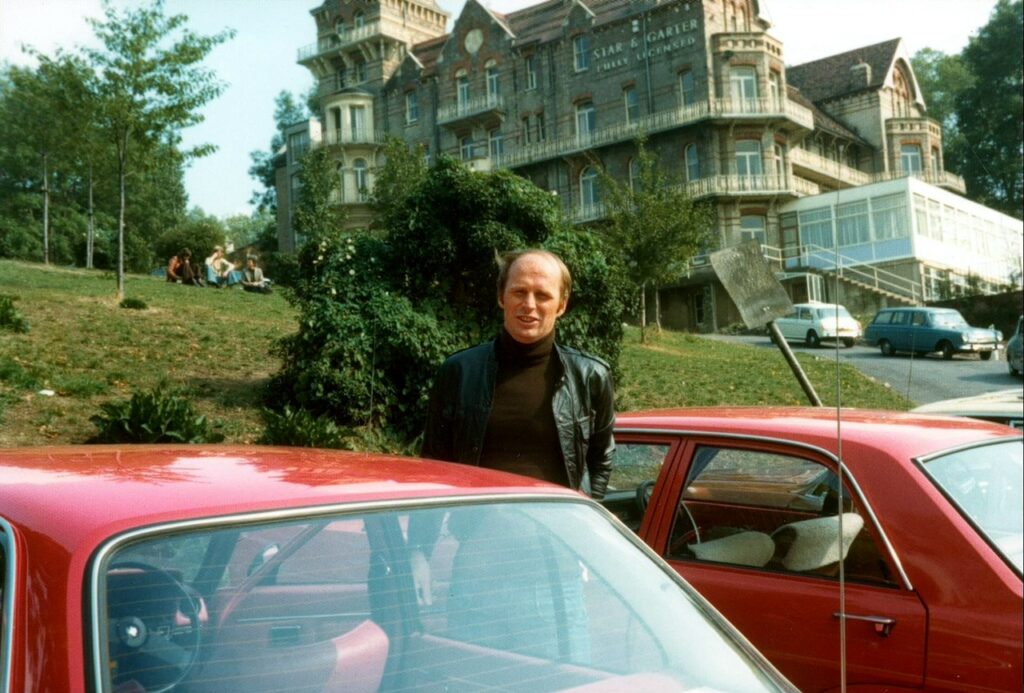

Founder

Managing Director

Application Specialist

Service and Manufacturing France

The Sofinn group of companies was founded in 1976. The purpose of the group was the introduction of Finnish High Tech in Western Europe. Main fields of activity:

1976: Sofinn SA equipment for the pharmaceutical and biotech industry. The company introduced a new type of water still for the pharmaceutical industry which with time became the world leader in its own field. The company also became one of the leading suppliers of sterilisation equipment. The UK and French companies further developed their own technology for the storage and distribution of water for injection. The activity required a thorough understanding of all technical aspects as well as the corresponding requirements of the US FDA.

1976-2002: Complete production lines for the wood based panel and parquet industries. The activity concentrated on France and French speaking Africa and was built up during a time period of 25 years. When devested in 2002 to the Raute corporation of Finland, Raute was by far the leading supplier of such equipment in France.

1976-1983: Equipment for the glass industry as well as its production. The main activity was first the building up of the sales of laminated windscreens in France on a number of European markets. The group became an important windscreen wholesaler in Germany. The latter successfully devested to the Finnish company Tamglass in 1983.

1982-2000: Complete lines for sawmills. The co-operation with the Veisto Group resulted in the introduction of a new type of high productivity Hew saw in France.

The company became one of the leading suppliers of destillation and sterilisation equipment in Europe. The UK and French companies later developed their own technology for the storage and distribution of water for injection. The activity required a thorough understanding of all technical aspects as well as the corresponding requirements of the US FDA.

The activity concentrated on France and French speaking Africa and was built up during a time period of 25 years. When devested in 2002 to the Raute corporation of Finland, Raute was by far the leading supplier of such equipment in France.

The Finn-Aqua representation in the UK grew to a market leading position for WFI, Pure Steam and Autoclaves. The UK business was headed by Philip Precious. Under Philips leadership Sofinn UK achieved a market leading position in WFI and sterilisation in the UK and Ireland.

Finn-Aqua SA change de nom pour Pharmtec SA en lien avec la vente de la société finlandaise Finn-Aqua (Santasalo Sohlberg) à Amsco Inc.

Sofinn Group shareholders invest in the Finnish biotech company DelSiTech Ltd specialised in controlled release.

Sofinn’s joint acquisition of majority stake in Aqua-Nova in Sweden together with Mr Lennart Kärrberg a leading expert in thermodynamics. The company is a leading supplier of distillation and pure steam generators for the pharma and biotech industries.

Lytzen is the world’s leading Hot Air Sterilser producer. Cooperation between Lytzen and Sofinn dates back to 1981.

Sofinn subsidiary Pharmtec SA starts Strategic co-operation agreement with Tofflon for the production of the Aqua-Nova water stills for the Chinese market. Tofflon are today the world’s leading supplier of pharmaceutical Freeze-Dryers.

Pharmtec SA Opens factory-workshop in Normandy for building of Effluent Decontamination units and a workshop for assembly, installation and after sales service.

Specialist in pure, clean and sterile applications

Tel: + 44 1633 415 355

Email : uk@sofinn.com

Request more information by visiting our contact page and filling out our contact form.

A member of our team will be in touch.

Email us: uk@sofinn.com

Tel: + 44 1633 415 355

Email us: ir@sofinn.com

Tel: + 44 7539 432 772

Email us: fr@pharmtec.biz

Tel: + 33 (0)1 39 10 31 31

Founded in 1981, Sofinn UK Ltd provides a comprehensive range of state of the art equipment for the pharmaceutical and biotech industries. We operate across Europe providing solutions via multiple products and brands. We also have offices in the UK and France.

WFI and Pure Steam: two similar and yet different fluids

Simultaneous production is possible thanks to the unique Aqua-Nova technology. Here’s how!

Following strong interest

We only send out emails once a month and we only share information that is relevant and interesting for our industry.

Website by Power Box Creative