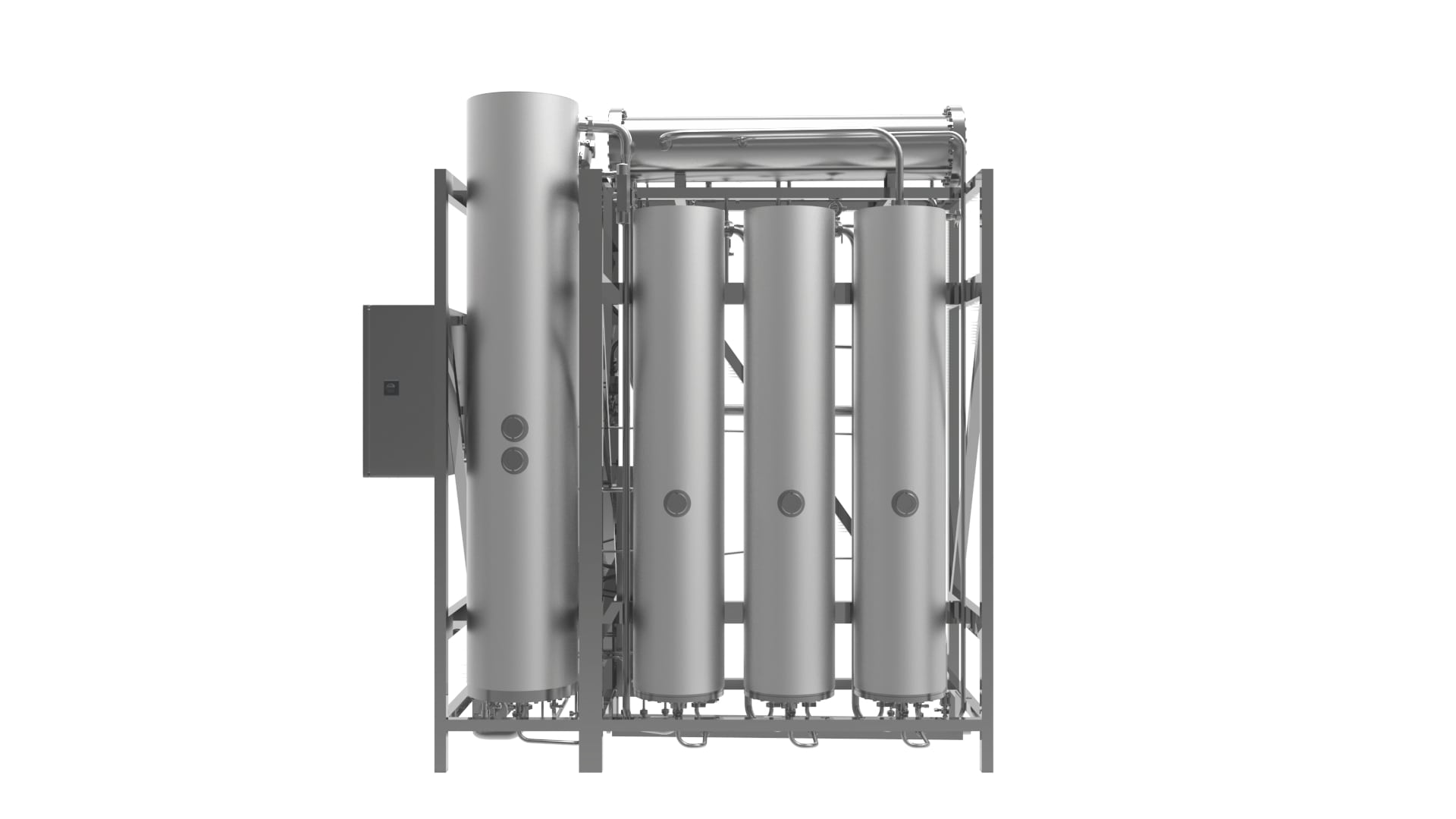

Aqua-Nova represents the 3rd generation of Multi-effect WFI Water Still where proven, reliable technique and modern design are combined in an efficient way. Our original ‘float’ type design from 1981 heat exchangers and low steam velocities combined with cyclone separation and proportional media regulation, is still the most reliable way of producing Water For Injection (WFI) and Pure Steam (PS) as per the latest, international pharmacopoeias.

User advantages of Aqua-Nova stills

- The most reliable WFI still on the market

- No feed water tank necessary.

- Extremely simple heat exchanger leak test without counter pressure.

- True cyclone separation of particles with direct discharge to drain.

- Easy service and maintenance due to simple and effective design.

Product Specification

The Aqua-Nova Multi-effect Water Still operates using energy-efficient multi-effect principles without internal moving parts, is quiet, and fully automatic. It utilizes steam from the 1st column to heat subsequent columns, saving energy. Distillate condensate is efficiently recycled, and all feed water is heated to >143ºC. The system self-regulates, eliminating the need for a feed water tank. It can function as a Pure Steam Generator separately or produce both WFI and Pure Steam simultaneously in different modes (WFI, Pure Steam, or both). The units are built with AISI 316L material and comply with cGMP guidelines, meeting pressure vessel code standards.

Sebastian Bjorksten

Managing Director Sofinn UK Ltd

“We will work with your team to select the best products and specifications that meet your needs. We can handle everything from your first phone call to the installation.”

Call: +44 7539 432 772

Email: sebastian.bjorksten@sofinn.com

Electrically Heated Multi-Effect Stills

Only the 1st column is heated by means of industrial steam or electricity where the steam produced from the boiling water in the column is used as heating of the 2nd column and the steam from the 2nd to heat the 3rd and so on to the last column. The distillate condensate is led stepwise from heat exchanger to heat exchanger regaining the flash-energy to the process and thereafter led to the condenser.

The first column of the standard still can be used separately as an independent Pure Steam Generator at full capacity or produce a limited of Pure Steam with reduced WFI production during normal operation. The Combi units are designed to produce WFI and Pure Steam simultaneously without any reduction of either WFI or Pure Steam. The Combi unit switches automatically between the production of either:

Mode A. WFI and Pure Steam simultaneously.

Mode B. WFI only.

Mode C. Pure Steam only.

| Product Name | Connection | Production l/h |

|---|---|---|

| E-100-3 | 28 kW | 100 |

| E-200-4 | 44 kW | 200 |

| E-300-4 | 65 kW | 300 |

| E-500-6 | 74 kW | 500 |