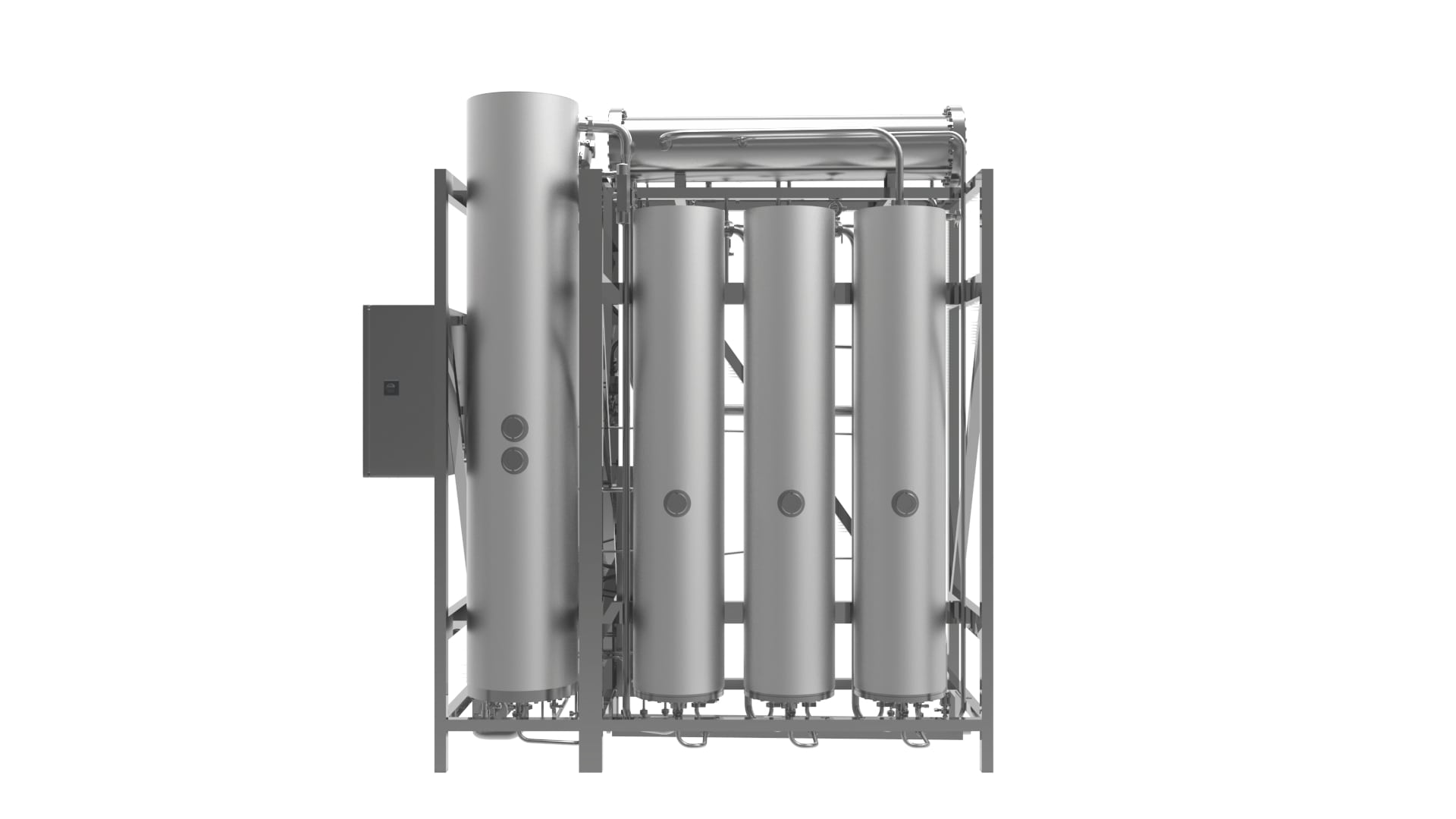

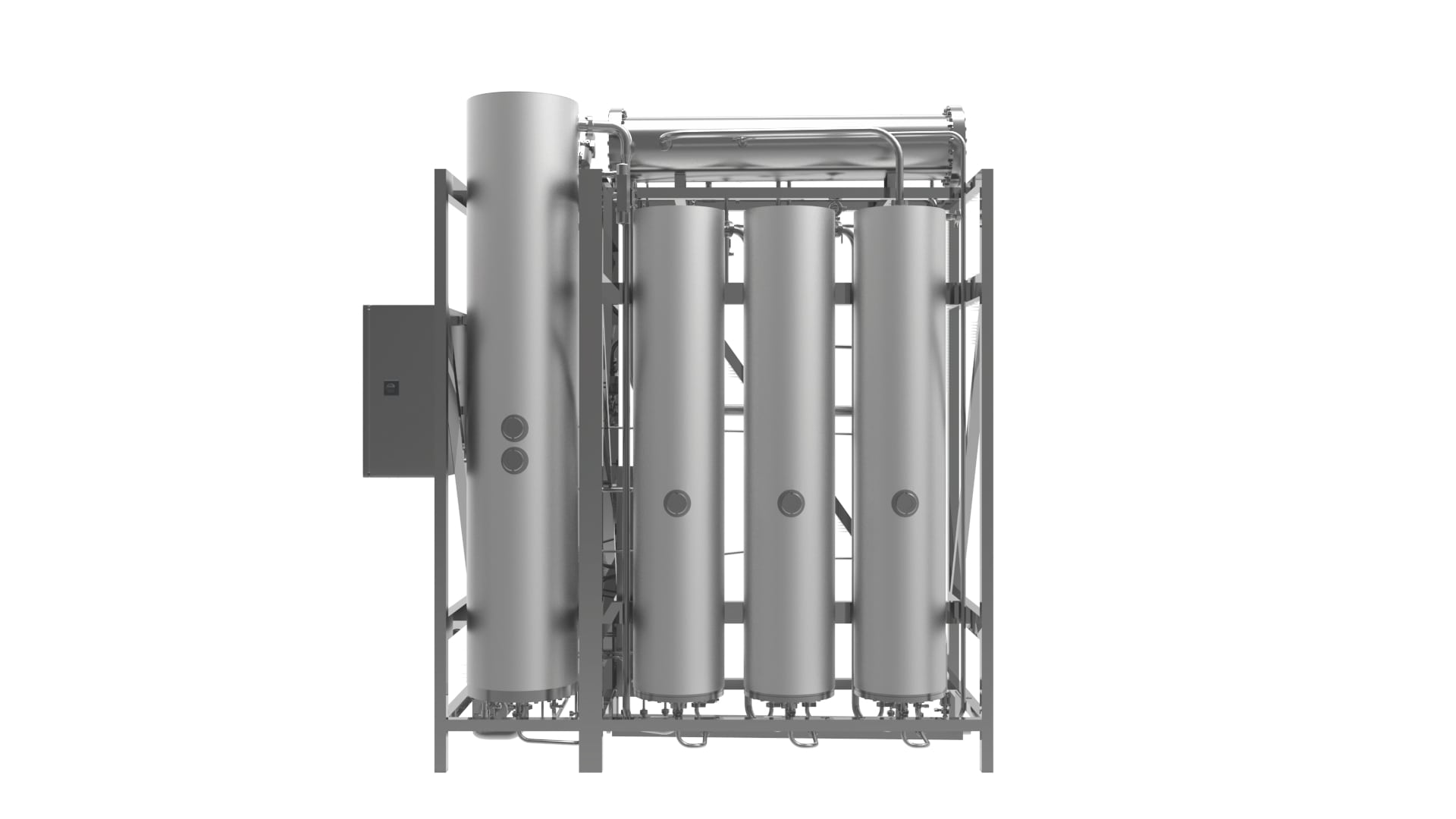

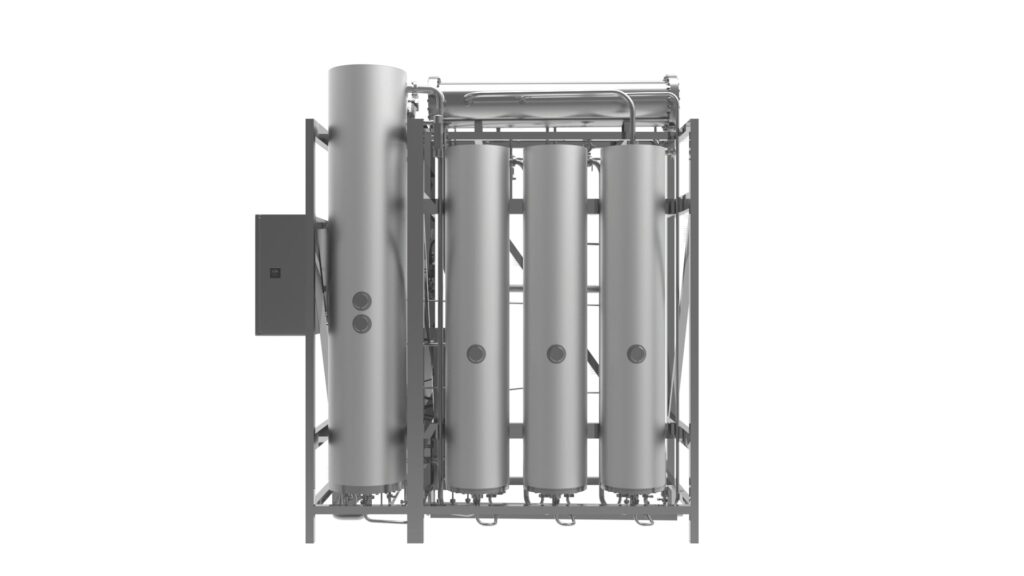

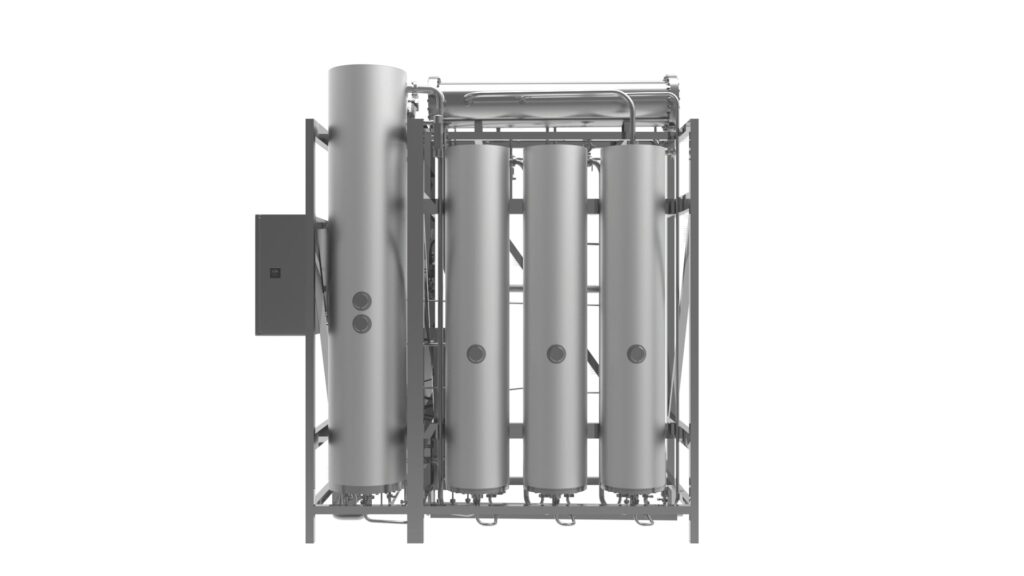

Experience efficiency and reliability with Aqua-Nova’s steam-heated multi-effect stills. Our cutting-edge technology ensures precise distillation, making it the perfect choice for pharmaceutical and biotech industries.

Advantages of Aqua-Nova Stills

- The most reliable WFI still on the market

- No feed water tank necessary.

- Extremely simple heat exchanger leak test without counter pressure.

- True cyclone separation of particles with direct discharge to drain.

- Easy service and maintenance due to simple and effective design.

Product Specification

Introducing Aqua-Nova, Europe’s leading WFI equipment. Our reliable, tank-free design and innovative technology ensure top-notch quality and efficiency. With Aqua-Nova, you get the most reliable WFI still, simple heat exchanger tests, and true cyclone particle separation for superior water quality. Experience enhanced efficiency and reliability with Aqua-Nova.

Sebastian Bjorksten

Managing Director Sofinn UK Ltd

“We will work with your team to select the best products and specifications that meet your needs. We can handle everything from your first phone call to the installation.”

Call: +44 7539 432 772

Email: [email protected]

Steam Heated Multi-effect Still

Our systems come with the option for semi- or fully automatic function, including automatic start/stop on signal from WFI tanks and discharge of sub-standard distillate during MULTI-EFFECT Still Start and stop operations. Automatic surveillance and alarms for critical process values are standard features.

Prior to delivery, all AQUA-NOVA stills undergo a Factory Acceptance Test (FAT) at our facility, which is documented and verified by an independent laboratory for distillate quality.

The software is developed in accordance with GAMP specifications. For those who request it, comprehensive Pre-Installation Qualification (IQ) and Operational Qualification (OQ) documentation will be provided, including calibration documents. Our standard delivery documentation encompasses authorized pressure vessel drawings with material and weld certificates, mechanical component documentation and manuals, as well as electrical and instrument documentation and comprehensive machine installation, operation, and service manuals.

| Type & Columns | Plant Steam Pressure bar g | Production l/h |

|---|---|---|

| S-100-3 and 4 | 3-8 | 100 - 200 |

| S-200-3 and 4 | 3-8 | 200 - 400 |

| S-300-4 and 6 | 3-8 | 300 - 600 |

| S-500-4 and 6 | 3-8 | 500 - 1 100 |

| S-1000-5 and 6 | 4-8 | 1 200 - 2 100 |

| S-2000-5 and 6 | 4-8 | 2 800 - 4 100 |

| S-3000-6 and 8 | 5-8 | 4 400 - 6 200 |

| S-4000-6 and 8 | 5-8 | 5 800 - 8 000 |