Sack discharging stations provide a convenient and compact possibility of discharging sacks in a low-dust manner. Fully contained sack discharging stations for dust-free emptying are also available.

Top level information

Depending on the requirements, the dust can be separated with an integrated filter with product return, or an external filter in combination with a dedusting system. The exhaust unit starts automatically when the front flap is opened. As always, HECHT Sack Discharge Stations can be configured according to the customers specifications needs:

- Filtering options

- No product carryover during the exhaust process

- Protective vibrating sieves of different mesh-sizes for separation of contaminants

- Big variation on materials and surfaces available on request

- Operator-friendly Integration of the filter elements

- Little required space

- Scissors lift for ergonomic handling

- Available in hygienic design

- Empty-sack disposal and compactor (standard or hygienic design)

- Mobile Version with fixed and swivel castors

Test a Sack Station

Sack Discharge Stations can be rented for tests at the customer’s site: in these applications ergonomic is key from an operator’s point of view.

Helena Artama

Application Specialist Sterilisation and Powder Handling

“Let’s get in contact with the HECHT expert in BigBag Discharge. Together we will find the optimal connection system and select the right options for your application.”

+ 33 (0)6 83 28 95 43

helena.artama@sofinn.com

SE-RVS

HECHT‘s SE-RVS is a sack discharging station in hygienic design with integrated vibrating sieve for dissolution of small lumps and separation of contaminants. The integrated protective vibrating sieve holds back all impurities that must not get in touch with the product or that exceed a defined particle size (protective sieve). Furthermore, small lumps can easily be dissolved. Because of the internal vibration decoupling, no hygienically critical transition sleeves are needed (one-piece casing). If necessary for product changes, the sieve can be exchanged without using any kinds of tools.

Due to the round design, the SE-RVS can easily be cleaned and is suitable for the use in Ex-zones. A ventilator behind the external filter generates a continuous low pressure in the system in order to avoid the emission of dust while discharging the sack. The suction can be switched on automatically when opening the front flap.

SE-CS Contained Sack Discharge

To ensure effective operator protection, it is essential to contain the product at the production site, from the first step in the process until final packaging. In addition, the risk of cross-contamination is prevented to ensure operator protection. When using hazardous substances, our systems provide the safety to work without personal protective equipment at any time. The pressure-controlled High Containment Sack discharge station SE CS ensures dust-proof, contamination-free discharge of your sacks up to OEB Level 5, meeting the highest hygienic requirements. A glovebox with connected continuous liner packages makes sure that the system is hermetically sealed at any time. The sacks are provided in an isolator via an airlock. Negative pressure prevents dust from escaping, and the personnel does not come into contact with the product.

The product is fed through an airlock with continuous liner on the left-hand side of the isolator. The liner is closed twice after the sack. The operator handles and opens the sack inside the glovebox using the gloves. The sack can then be separated from the endless liner and emptied. Then, the continuous liner is closed twice after the next sack, and the already emptied sack is cut off. In the next step, the empty sack is directly disposed of into a waste bin through a pipe on the right-hand side. At no time are contaminated surfaces open. The pressure inside the sack discharge Station is continuously monitored in order to prevent the escape of air and oxygen.

SE-H- and SE-H-EF (Intergrated filter) stations

The SE-H is available as a basic model for on-site dedusting or with top-mounted filter. The spacious hopper consists of a product buffer of 260 liters. The large grid of 50 mm x 50 mm can be easily exchanged without any tooling.

Due to the compact construction it can be used in confined space conditions.

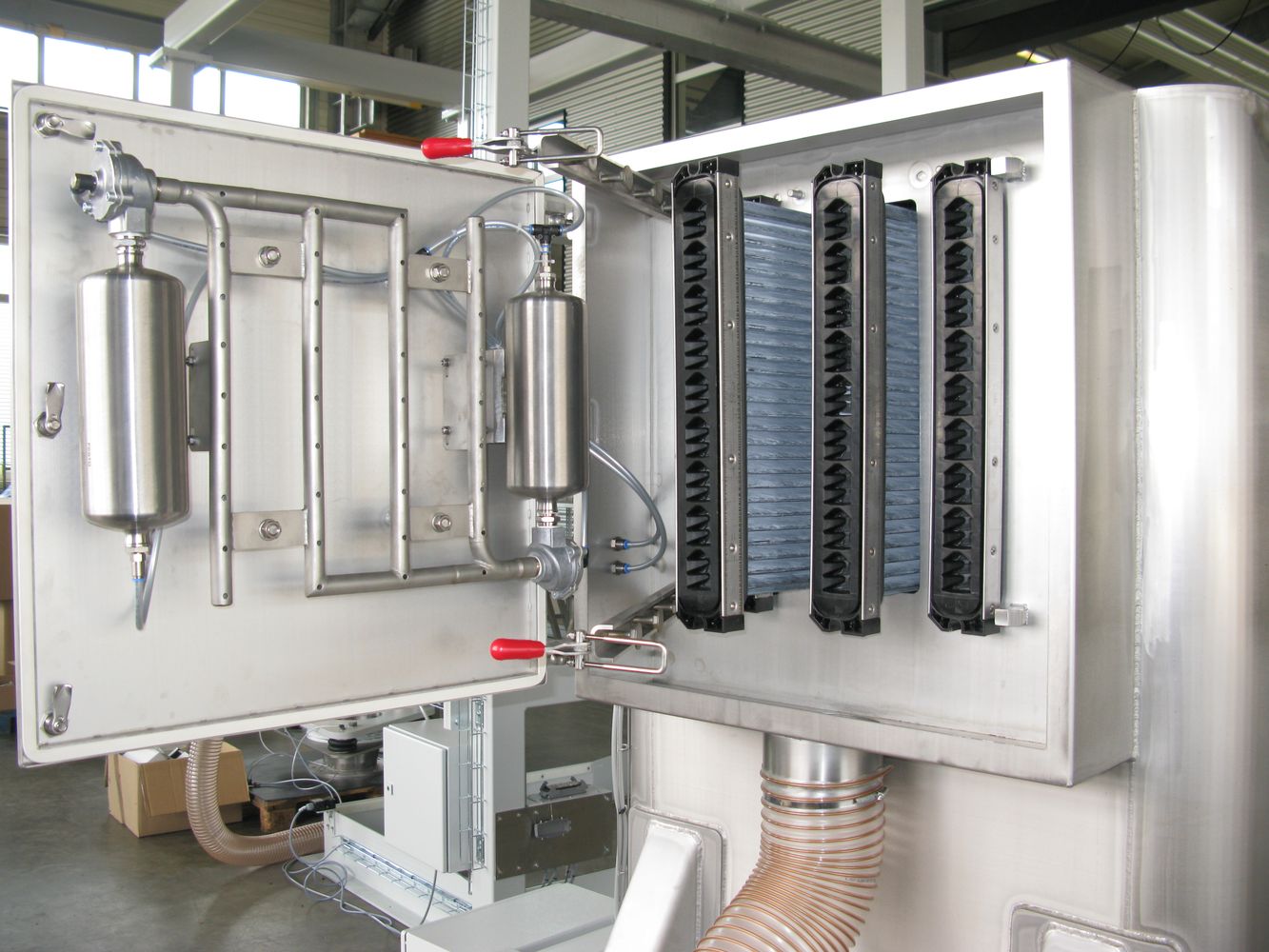

The sack discharge station SE H-EF with integrated filter and protective vibrating sieve is used for hygienic applications in many different areas. The integrated filter (PE filter with PTFE coating and extremely high separation efficiency) avoids product carryover and thus product loss. The easy-to-clean and hygienic design as well as the user-friendly Integration of the filter elements simplify the handling of any kind of products.

The operator opens the filling flap and places the sack is onto the support table. Using a knife, the Operator opens the sack and empties the product on a vibrating protective sieve. The empty sack can be disposed of through a laterally mounted empty sack disposal chute (optional). After the discharge the operator shuts the front flap. If required, the sack discharge station can be cleaned using water.