The washing machine is suitable to wash vials with automatically continuous or intermittent motion.The machine ensures eremoval of at least 3 log of particulate contamination (particles such as glass, fibers,etc.).The washing cycle can include recycled water spraying,WFI spraying and compressed air blowing.

Fastest delivery time

Tofflon sets the standard in the pharmaceutical and biotechnology industries, combining top-tier freeze-drying technology with unmatched efficiency. Our equipment guarantees superior performance and reliability, ensuring the best price-to-quality ratio. Tofflon stands out for its industry-leading short delivery times, exemplifying commitment to customer satisfaction and excellence.

In Process Quality

In our commitment to in-process quality control, we meticulously conduct a variety of critical tests and validations, including the Shelves Temperature Uniformity Test, SIP (Sterilization in Place) Temperature Distribution Test, CPI (Critical Process Indicator) Validation, and Filter Integrity Test (WIT – Water Intrusion Test), ensuring the highest standards of reliability and efficiency in our processes.

Yan Shen

Project Manager

“We will work with your team to choose the best products and specifications for your requirements. We can handle everything from the first phone call to installation.”

Call: + 33 6 31 55 95 79

Email: yan.shen@sofinn.com

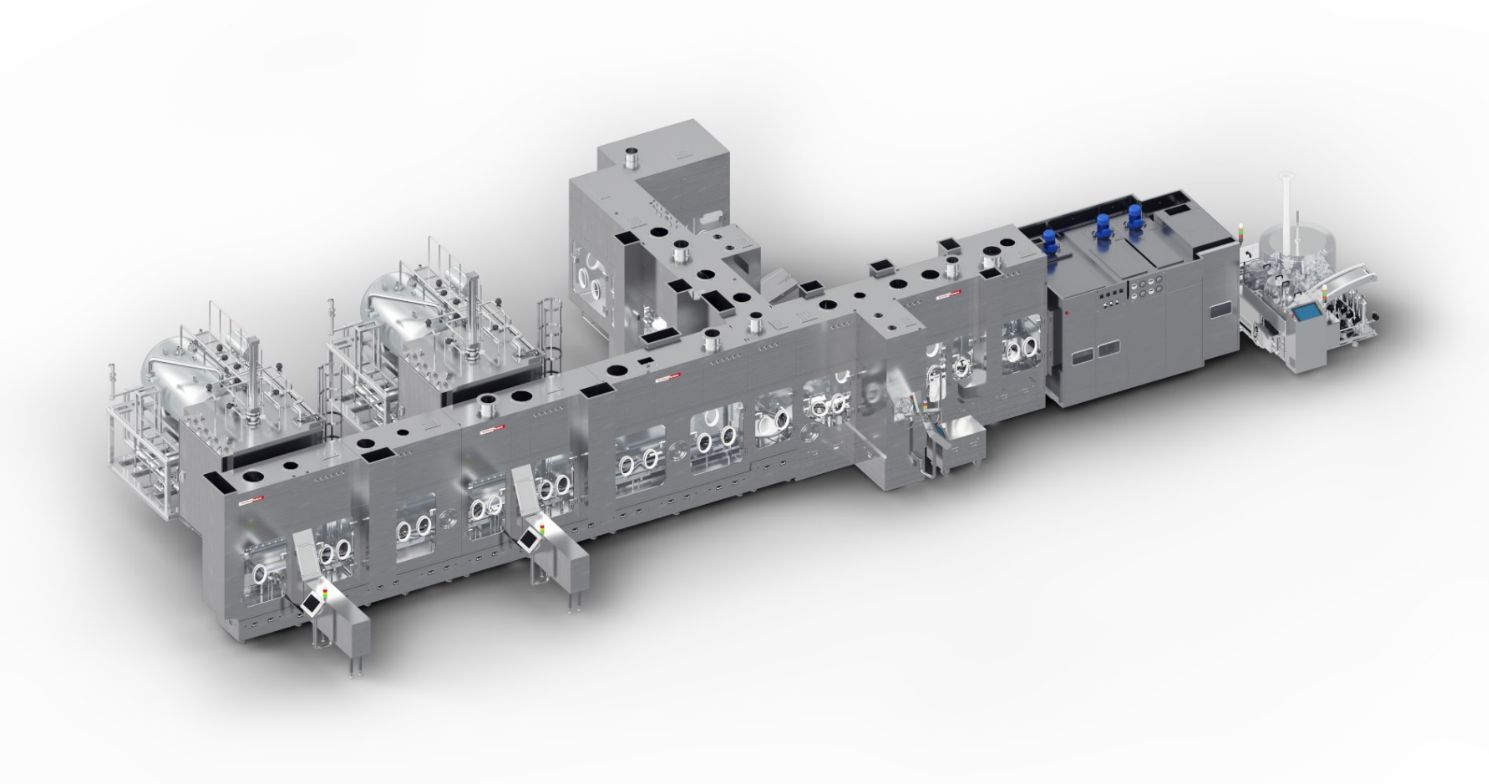

Vial Washing Machine

Key Features:

- Intermittent or continuous motion machines are available.

- Full servo motor control.

- Ergonomic machine operation and format recipe management system.

- Flexible processing steps and capacity setting. Simple format conversion.

- Sanitary piping design:ASME BPE or ISO SMS Standard; TIG automatic orbital welding; boroscope inspection, passivation and electropolish.

- Pressure and temperature of the various media are monitored to ensure good and constant performances.

| Model | FWV 02-10 | FWV 02-20 | FWV 02-30 | FWV 02-40 | FWV 02-50 |

|---|---|---|---|---|---|

| Vial (ml) | 2 -1000 | 2 - 50 | 2 - 30 | 2 - 20 | 2 - 20 |

| Mechanical Output (vph) | 6 000 | 12 000 | 18 000 | 24 000 | 30 000 |

| WFI Supply (m3/h) | 0,4 | 0,6 | 0,7 | 0,8 | 0,9 |

| Compressed Air Supply (L/min) | 600 | 950 | 1 100 | 1 300 | 1 500 |

| Power Supply (kW) | 7 | 12 | 12 | 12 | 12 |

| Dimensions L x W x H (mm) | 2200 x 1400 x 1200 | 2400 x 2400 x1500 | 2400 x 2400 x1500 | 2600 x 2600 x1500 | 2600 x 2600 x1500 |

| Weight (kg) | 1 500 | 2 800 | 2 800 | 3 500 | 3 500 |