What does containment mean in the context of powder handling?

Le confinement est l’encapsulation de matériaux dangereux. L’échappement de substances dangereuses du lieu de travail (protection de l’opérateur) ou la contamination d’un produit par des

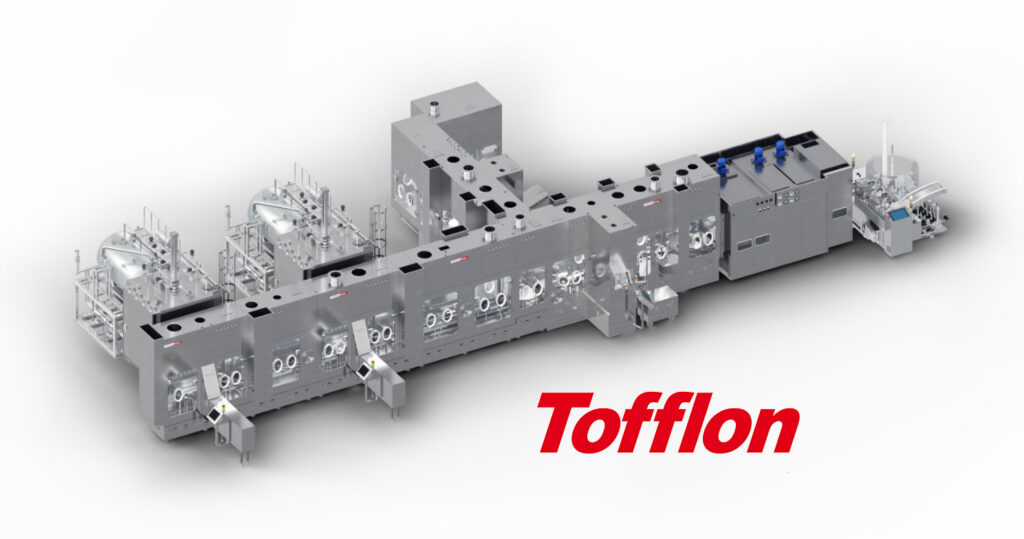

Tofflon Filling Solutions offers cutting-edge technology compliant with FDA and GMP standards, ensuring safety and efficiency in pharmaceutical production. Our equipment excels in precision and accuracy, minimising waste and bolstering product integrity. Designed for scalability, it adapts to companies of all sizes. High-speed capabilities drastically reduce filling times, while its flexibility accommodates a wide range of liquids and viscosities.

We provide services at all stages in the lifetime of the equipment, keeping the equipment in good working order and prolonging the lifetime of the installations.

Founded in 1976, Sofinn Group of companies provides a comprehensive range of state of the art equipment for the pharmaceutical and biotech industries. We provide turnkey solutions for destillation, sterilisation, lyophilisation, decontamination, washing and filling. accusantium doloremque laudantium.

As your trusted partner in service and equipment solutions, we are deeply committed to quality, specialising in sterilising water and pharmaceutical equipment.

Specialised in Quality: Focused on sterilising water and pharmaceutical equipment.

Customer-Centric: Your satisfaction drives our exceptional service.

Project Simplification: Making even the most complex tasks manageable.

Timely Delivery: Get what you need, when you need it.

Tailored Solutions: Match your project with the most effective technology.

Request more information by visiting our contact page and filling out our contact form.

A member of our team will be in touch.

Email us: [email protected]

Tel: + 44 1633 415 355

Email us: [email protected]

Tel: + 44 7539 432 772

Email us: [email protected]

Tel: + 33 (0)1 39 10 31 31

Founded in 1981, Sofinn UK Ltd provides a comprehensive range of state of the art equipment for the pharmaceutical and biotech industries. We operate across Europe providing solutions via multiple products and brands. We also have offices in the UK and France.

Le confinement est l’encapsulation de matériaux dangereux. L’échappement de substances dangereuses du lieu de travail (protection de l’opérateur) ou la contamination d’un produit par des

We only send out emails once a month and we only share information that is relevant and interesting for our industry.

Website by Power Box Creative