The HECHT Big bag station range goes from basic stations to discharging of high potent powders using the patented EC “Easy Connect” technology. Various options are available.

Hecht Big Bag Discharge stations

An FIBC discharge station mainly consists of 3 components:

- The Connection system is the core component. Different possibilities are available according to the required level of containment.

- The basic frame: big bag lifting system, support table with or without vibration and massaging options, and the frame for fastening the connection system.to the next process step,

- Interphase to the next process stem e.g. dosing unit, scales, suction shoe with pneumatic conveying, mixer, reactor…

Helena Artama

Application Specialist Sterilisation and Powder Handling

“Let’s get in contact with the HECHT expert in BigBag Discharge. Together we will find the optimal connection system and select the right options for your application.”

+ 33 (0)6 83 28 95 43

Different Connections for BigBags

All Connection Systems are designed for safety and optimal ergonomy. They are also available as components to be integrated into larger systems or can be rented.

The Connection System for the Big Bag Outlet is selected according to several criteria. The level of containment can go from coarse protection of the operator up the OEB 5 or 6 level protection.

All connection systems can be delivered in various materials and many different options are available: Alex-versions, WIP, connection options etc.

CAS

The Compact connection system CAS is a cost-efficient starter version for low-dust discharging (up to OEL < 1.000-5.000 μg/m3) of FIBCs (with or without inner liner).

The CAS is designed for handling non-hazardous products in simple industrial, chemical, food or pharmaceutical applications.

AAS

The outlet connection system AAS is used for low-dust discharging (up to OEL 1.000 – 5.000 μg/m3) of FIBCs with or without inner liner and features a double protection against dust leakage.

The outlet connection system distinguishes itself by its easy handling. For discharging, you just have to pull the closed FIBC outlet over the inner tube and fix it using the sealing flange. The latter is possible using the two-hand lever mechanism, which makes sure that the operator cannot squeeze his/her fingers between the sealing flange and the outer tube in case of proper handling.

AAS-EF (with dedusting)

The outlet connection system with integrated dedusting filter AAS-EF is the further development of the proven AAS.

It is used for low-dust discharging (up to OEL 100 – 1,000 μg/m3) of slightly hazardous and dusty bulk solids from FIBCs and protects the room against contamination.

Due to the integrated dedusting filter, the connection to an external filter unit is no longer necessary.

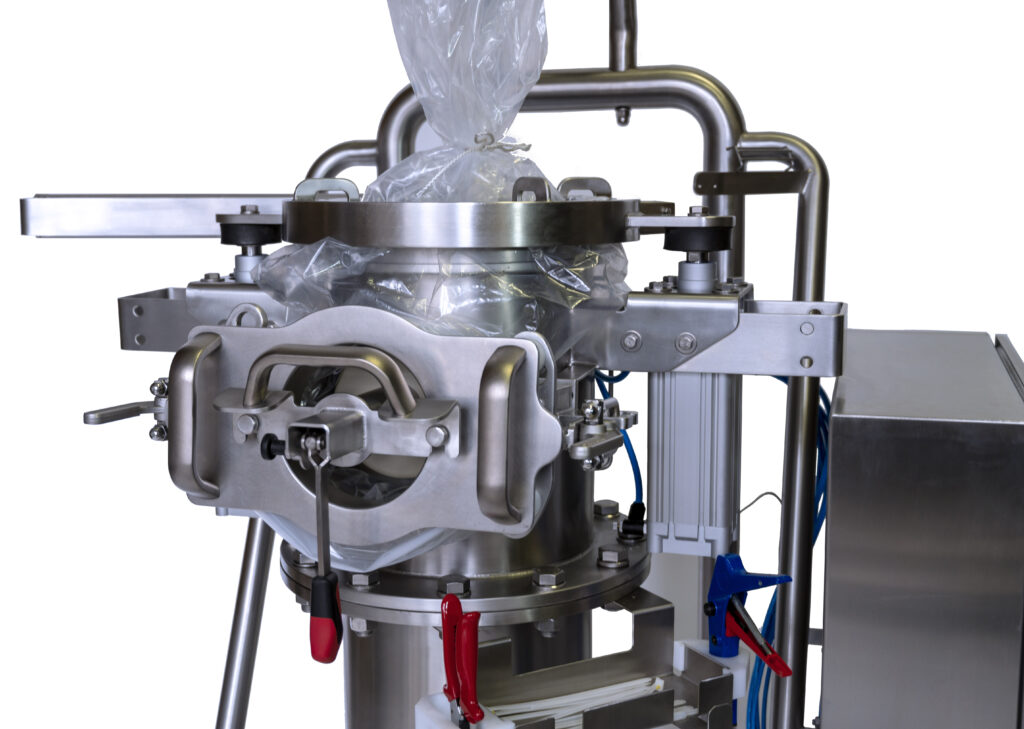

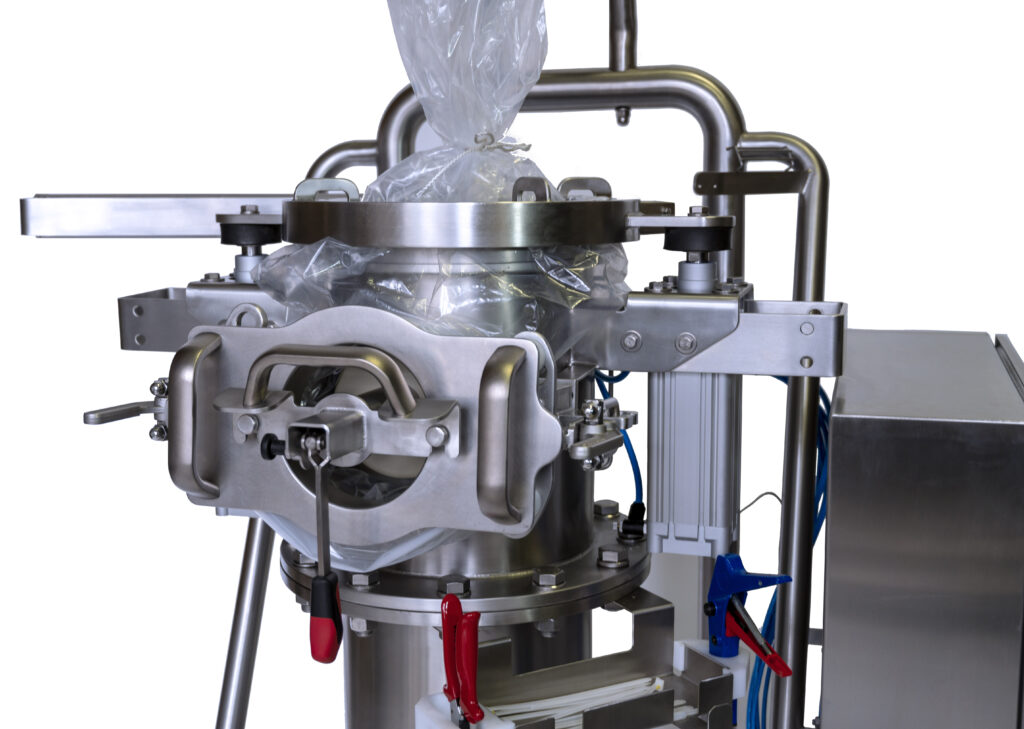

LAS-EC "Easy Connect" (OEB5 containment version)

The outlet connection system LAS-EC „Easy Connect“ (patent-pending) enables a fast automatic, safe and ergonomic discharging of BigBags with internal liner up to a Containment level of OEB 5. Operator, environment and product are consequently protected from contamination and impurities. No consumables such as O-rings are needed.

Various options are available, WIP, electropneumatic or pneumatic control, etc.

SoliValve® Split-cone System

The SoliValve® Split-cone System enables fully automatic, low-contamination as well as contained discharging and dosing (up to OEL 10-100 μg/m3) of slightly hazardous products from special BigBags with conical closure (SoliBag®).

By controlling the active valve, product can be dosed from the BigBag. In the case of partial discharge, the SoliBag® is closed again by the integrated conical closure after disconnection and can be connected again and dis- charged at a later point in time.

CIP nozzles (Cleaning in Place) and a cleaning cover allow for hygienic cleaning of the entire connection system. The cleaning efficiency can be prevalidated at the Factory Acceptance Testing (FAT).