The mechanical parts of a Lytzen oven are known to last for decades., but control systems have a limited lifecycle. Imagine the scenario where your oven’s control system completely crashes and recovery is no longer possible.

The old control system (PLC Siemens Lytcon 2) of your Lytzen oven becomes obsolete with time and runs a risk of maintainability concerning Siemens components.

Additionally, the Yokogawa/Chessel Series 4100 chart recorders have also become obsolete for cycle data acquisition.

The up-grade of the Siemens control system of your oven to the newest Siemens LD4 version (panel-PC) allows you to do without a recorder while keeping the same functionalities necessary for the validation of your data cycle.

You will avoid stressful « run to fail » situations, chasing components from unusual sources in panic mode.

Instead, by up-grading, you will gain reliability, efficency, new functionnalities and a guarantee for spares parts for a long time onwards.

Pharmtec can offer you a complete turn-key service ensuring maximum reliability for your system and an extended life cycle for your equipment.

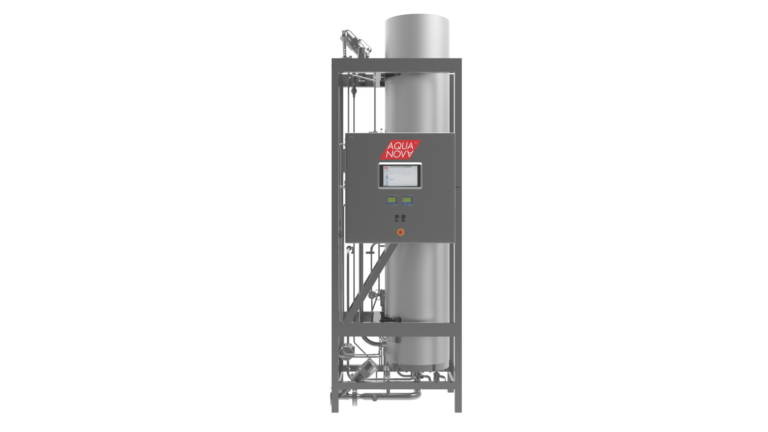

The new LD4 control system transforms the operation of Lytzen dry heat sterilisers into a seamless, automated experience. Optimised for efficiency, the system guides you through the entire sterilisation process, including drying, heating, and cooling phases, ensuring impeccable results every time.

Adhering to stringent FDA 21 CFR part 11 regulations, the LD4 offers optional enhancements to integrate audit trails, reinforcing data integrity and security. Simplify data management with comprehensive CSV file logging of crucial parameters, accessible through Ethernet or local storage, enabling effortless data retrieval and archiving.

Our system generates detailed reports in PDF, directly from the control interface, with options for both digital and paper formats. These reports cover everything from raw data and recipe settings to comprehensive cycle summaries and alarm logs. Moreover, reports can be customised, printed, and even emailed directly, ensuring your documentation is always up-to-date and readily available.

For added convenience, the LD4 boasts a multilingual interface, software calibration without third-party intervention, and an automatic start function to maximise productivity outside of regular hours. With the added security of a watch dog alarm, low disk space warning, and an uninterruptible power supply (UPS), your processes are safeguarded against unforeseen interruptions.

Lytzen’s commitment to quality extends to user management with a robust Windows-based system and software upgrades handled directly by you, ensuring your operations remain cutting-edge with minimal downtime. Choose the LD4 control system for a smarter, more reliable sterilisation process.