The Tofflon SZA Sterilization Tunnel is engineered for high performance and safety. It features negative pressure sealing for HEPA filters, and its interior is made of stainless steel to mitigate the risk of oxidation. Advanced functions like automatic air balance and door position control, which can be set to manual or automatic, further enhance its operational efficiency and reliability.

Uniform heat

The most important aspect of an ampoule sterilization tunnel in the pharmaceutical industry is its ability to consistently and effectively sterilize ampoules while maintaining product integrity. This involves precise temperature control and a validated sterilisation process to ensure the elimination of all microbial life, including spores. The tunnel must provide uniform heat distribution to guarantee that each ampoule receives the same level of treatment, which is crucial for meeting stringent regulatory standards.

Precision and speed

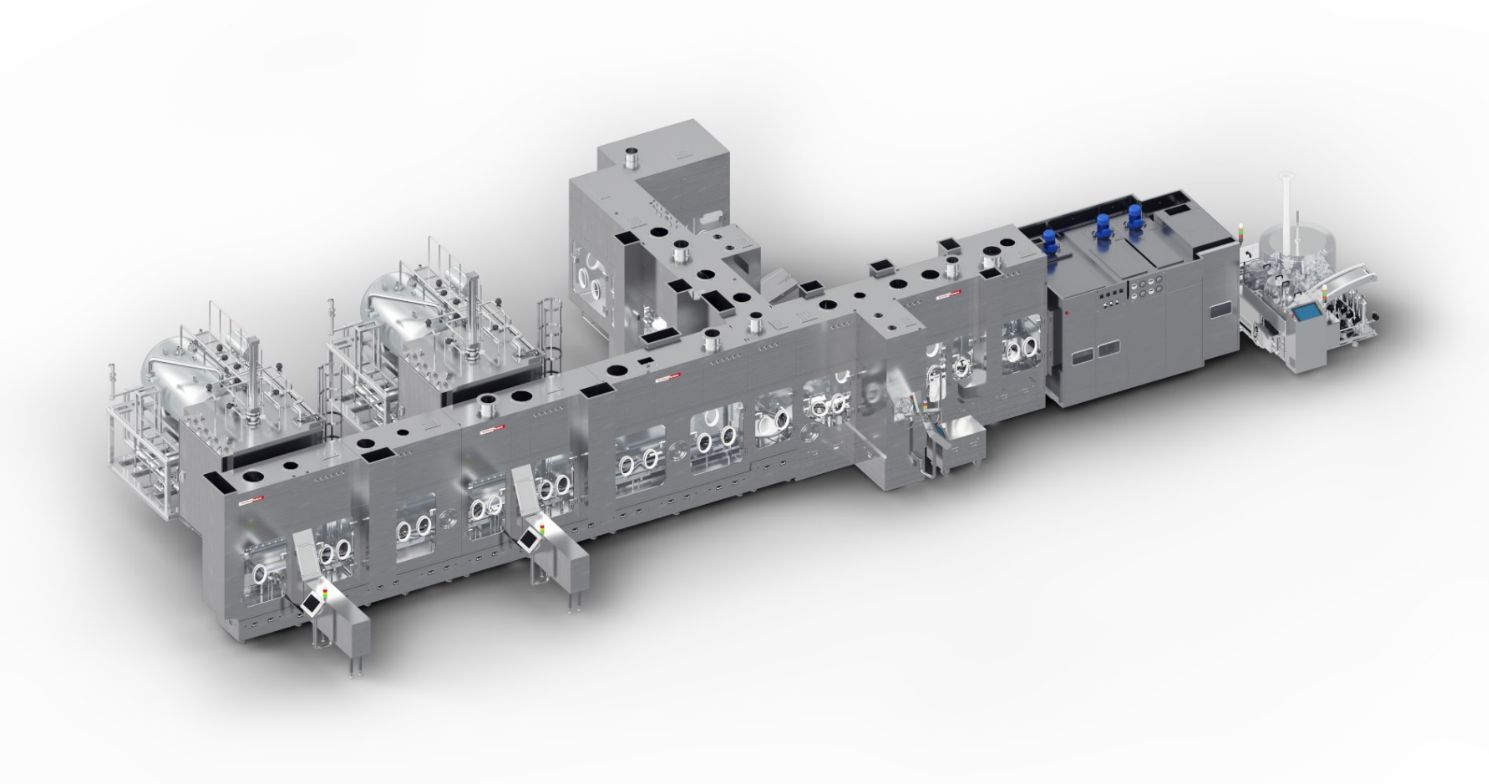

Experience precision and speed with Toffees’ Ampoule Filling Line – ensuring high-quality, contamination-free pharmaceutical packaging for maximum efficiency and reliability.”

Yan Shen

Project Manager

“We will work with your team to choose the best products and specifications for your requirements. We can handle everything from the first phone call to installation.”

Call: + 33 6 31 55 95 79

Email: yan.shen@sofinn.com

Ampoule Sterilization Tunnels

The Tofflon SZA Sterilization Tunnel is engineered for high performance and safety. It features negative pressure sealing for HEPA filters, and its interior is made of stainless steel to mitigate the risk of oxidation. Advanced functions like automatic air balance and door position control, which can be set to manual or automatic, further enhance its operational efficiency and reliability.

| Model | SZA620-F | SZA620-F |

|---|---|---|

| Ampoule Specification | 1ml-20ml | 1ml-20ml |

| Belt Width | 600mm | 600mm |

| Product Speed | 750 apm (2ml) | 750 apm (2ml) |

| Broken Rate | ≤0.2% | ≤0.2% |

| Qualified Rate | ≥99.9% | ≥99.8% |

| Cooling Type | Air Cooling: Room Temperature | Air Cooling: Room Temperature |

| Air Consumptiom | 3,000-3,500m3/h | 1,000-1,300m3/h |

| Water Consumption | N/A | 0.6-0.9 m3/h |

| Power | 54Kw | 54Kw |

| Weight | 3,500 Kg | 3,500 Kg |

| Dimensions (LxWxH) mm | 4400x1550x2300 | 4400x1550x2300 |