HECHT has different filling solutions for each application. In addition to components, ranging from simple dust-reducing to High-Containment Filling Heads, our portfolio includes complete Filling Stations for Big Bags or Sacks and Drums, part of which can be operated automatically.

Filling stations

Like discharging, filling of BigBags/Drums/Sacks is a typical application for us in all industries.

In addition to the BigBag/Drum/Sack of the customer and the filling performance, there are further points to be considered when planning filling processes. The dosing unit and the type of scale used are of crucial importance, since, together with the product properties, these systems affect the filling accuracy.

The materials used must also be considered. Will a local extraction system be sufficient for dust reduction, or will it be necessary to handle the products dust-free using Containment solutions?

Furthermore, the process integration must be carefully studied- HECHT is an expert in this.

Helena Artama

Application Specialist Sterilisation and Powder Handling

“Let’s get in contact with the HECHT expert in BigBag Discharge. Together we will find the optimal connection system and select the right options for your application.”

+ 33 (0)6 83 28 95 43

Different filling heads for BigBags

All Filling Heads are designed for safety and optimal ergonomy. They are also available as components to be integrated into larger systems or can be rented.

The Filling Head for the Big Bag/Sack/Drum is selected according to several criteria, starting from the diameter of the liner. The level of containment can go from coarse protection of the operator up the OEB 5 or even 6 level protection.

All Filling Heads can be delivered in various materials and many different options are available.

Depending on the application, a filling head for filling single sacks or liners can be integrated, or a filling head with continuous liner can be connected.

Further components for optional integration are weighing and dosing units, sampling systems, frames, as well as roller conveyors, Atex-versions, WIP

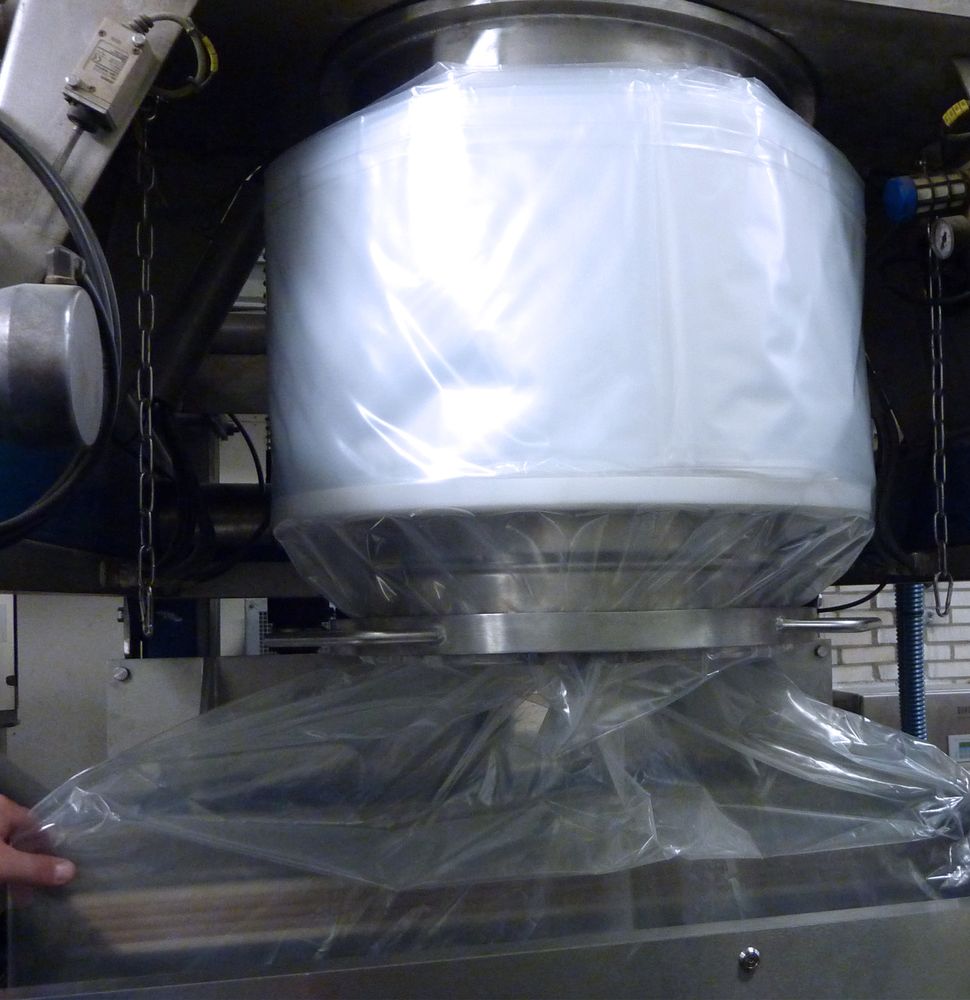

Continuous-liner filling head KB-EF

The continuous-liner filling head KB-EF enables closed filling of small bins without need for frequent bin changes.

Unlike single sacks, continuous liners can be filled in a completely closed process. This excludes the risk of environmental contamination during the bin change and ensures product and operator protection.

Due to a special folding method, up to 50 metres of liner can be provided on a liner carrier block. By pulling the liner out of the liner package block and into a drum or cardboard box, a liner bag is produced. This liner bag can then be inflated with slight overpressure and filled with product. During normal operation, no product will escape into the environment at any time.

The liner can be supplied as folded liner package, from antistatic with FDA approval to conductive with black grid pattern print.

Dust-reducing Filling Heads

Dust-reducing Filling Heads include:

- Filling Heads with bag clamp – hardly any dust reduction

- Filling Heads with inflation hose – low dust reduction

- Filling Heads with counter ring – medium dust reduction

- Filling Heads with inflation hose and counter ring – medium dust reduction

- Filling Heads with counter ring and inflatable seal – high dust reduction

Options include: integrated filter to avoid product loss in the aspiration unit, an active aspiration, adjustable counter ring for different diameters etc.

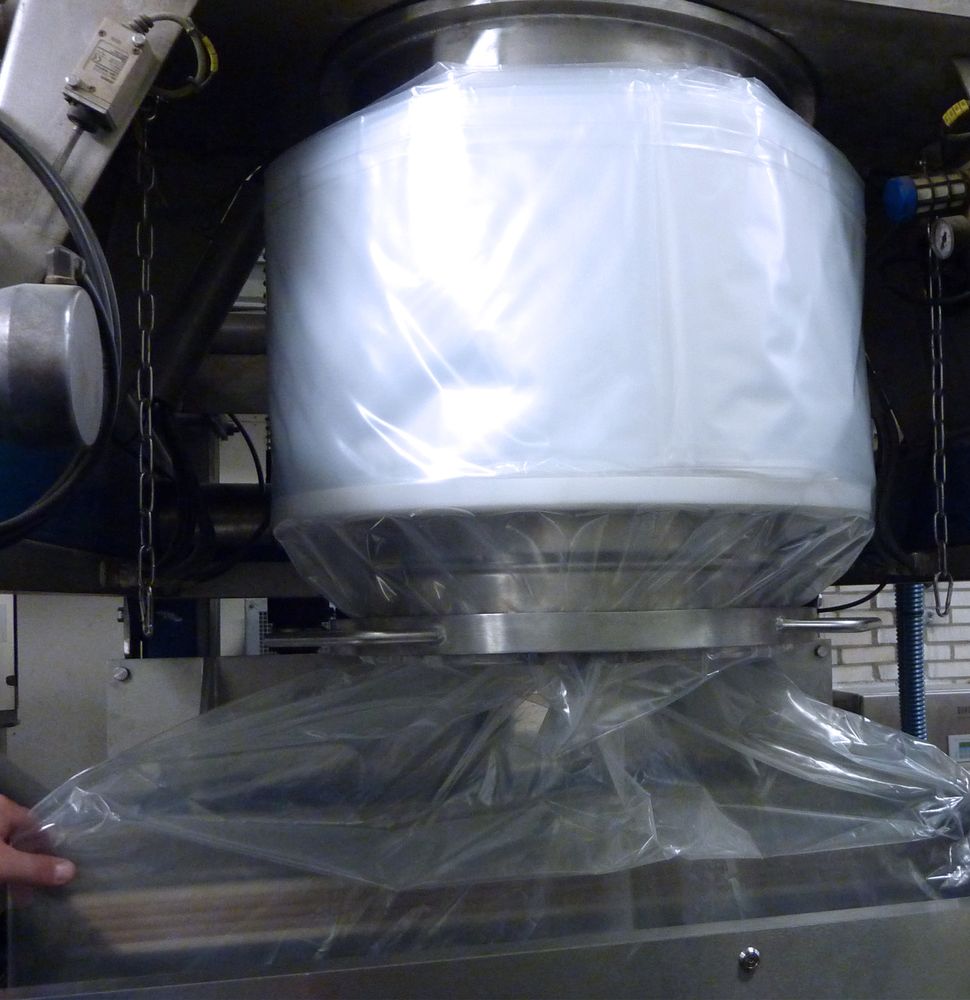

LBK-EC (up to OEB5 containment)

The LBK-EC liner filling head requires virtually no consumables such as O-rings. It is used for filling BigBags/Drums with inner liners. The simplified 3 – key operation, already known from the LAS-EC, relieves your operating personnel and at the same time provides more safety and comfort. Operating errors are virtually eliminated and handling has been improved once again. Technology tested up to OEB5 containment.