This new, mobile and cost-effective solution with optional transport trolley enables sampling in just a few steps.

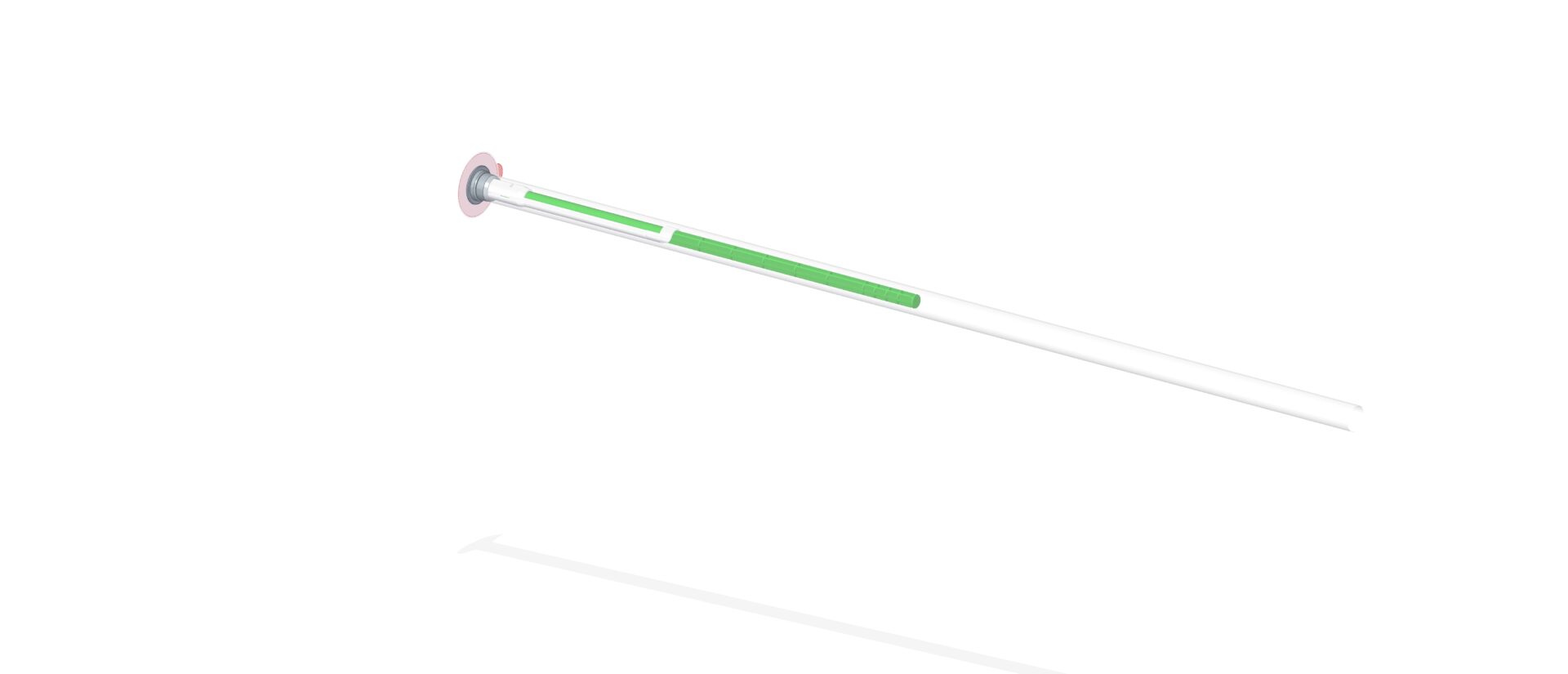

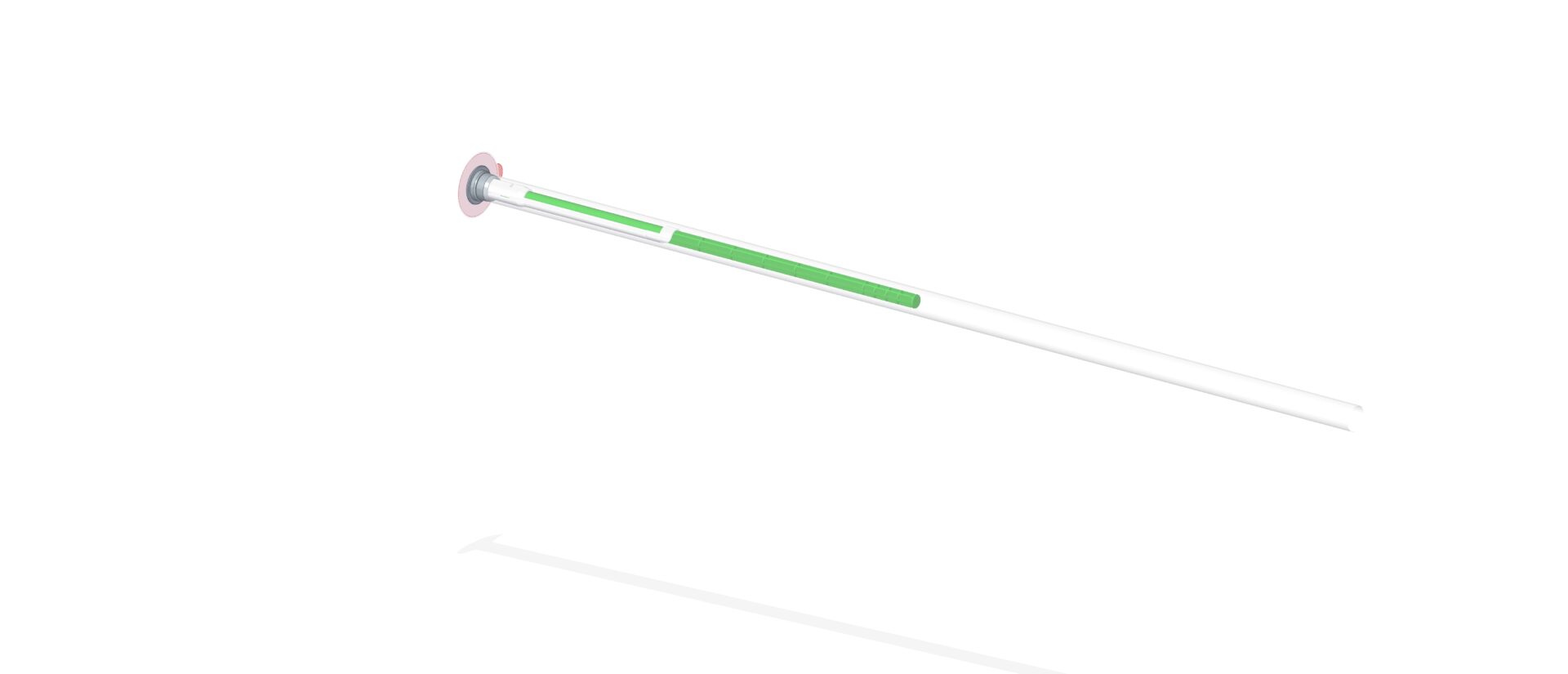

CPS Disposable Sampling Stick up to OEB5

The patent-pending Containment-Sampling-Stick CPS is used for sampling e.g. in incoming goods or for quality control of critical materials up to OEB 5.

This new, mobile and cost-effective solution with optional transport trolley enables sampling in just a few steps.

The resource-saving procedure with lance technology reduces your investment costs for additional containment and ensures avoidance of cross-contamination.

You either only use the disposable sampling stick or you also use the sampling trolley with the possibility to weld your sampling pouches. The mobile trolley includes a table, the welding machine, supports for the tools and is made of stainless steel.

All details are of importance in the CPS stick, which can be used without the trolley or independently. The idea is to place the stick on the product bag (inner liners of drums or Bigbags), then puncture through the liner and take out a sample of the product, and all this in a contained manner.

Sample simply in a contained manner

The CPS is the answer to how to sample a product from a big bag or a drum without having to open the inner liner. This system gives you maximum safety and flexibility in your sampling process.

Helena Artama

Application Specialist Sterilisation and Powder Handling

“Let’s get in contact with the HECHT expert in BigBag Discharge. Together we will find the optimal connection system and select the right options for your application.”

+ 33 (0)6 83 28 95 43

To complete the CPS Sampling Stick

The HECHT High Containment Closing System can be used for the sealing of the liner, instead of a thermo-weld.