HECHT samplers for powder or bulk products offer a simple handling whilst ensuring highest operator- and product protection.

Top level information

All HECHT samplers are of robust structure and especially developed for industrial applications with e.g. limited construction height.

The screw- or spoon-samplers are manual or automatic.

The CPP and CPS Sampling systems are designed for contained sampling .

The easy-to-dismantle designs allow a validate cleaning process. Various versions for different installation methods, individual set-ups and a flexible adjustability of the systems ensure an optimal user comfort and constant process reliability.

Test a HECHT Sampler

The HECHT samplers can be tested on site by the customer, or at the HECHT Test Centre in Pörnbach.

Helena Artama

Application Specialist Sterilisation and Powder Handling

“Let’s get in contact with the HECHT expert in BigBag Discharge. Together we will find the optimal connection system and select the right options for your application.”

+ 33 (0)6 83 28 95 43

Screw samplers

Whether for installation in silos or in downpipes – the HECHT screw sampler is the ideal solution for a representative sampling of any kind of bulk material. At individually selectable time intervals, the defined amount of product is sampled either automatically or manually by means of a hand wheel.

A pre-installed self-cleaning function guarantees the validity of the samples. Depending on our customers’ requirements, we offer various connections for matching sample vessels as well as different sealing valves.

The sampling screw rotates into the material flow, extracts a representative cross-section from the production flow and transports it into a sample vessel. An adjustable timer determines the sample quantity. Runtimes and pause times between two sampling operations are individually configurable. Before starting a further sampling process, the screw changes to reverse operation for a self-cleaning cycle. The product conveyed during the self-cleaning process is fed back into the production flow. Different systems like stuffing boxes / gland seals or a shaft ring seal ensure a final sealing. To guarantee a considerate and gentle product handling, it is recommended to install a counter-bearing.

- Downpipe: The sampler is installed between two flanges inside the downpipe

- Silo: The sampler is installed to a nozzle welded to a silo wall

An outlet cover (flap, ball valve or pinch valve) avoids product trickling or dust emission whenever the product vessel is disconnected. Depending on the type of sample vessel HECHT offers various connection systems:

- Spring steel wire clamp (for small and light sample quantities)

- Quick action clamp (for large and heavier sample quantities)

- Thread connections for bottles

HECHT screw samplers can easily be combined with a sampling magazine or a sample collector with endless liner.

Spoon samplers

The HECHT Spoon Sampler is a convenient inline sampling system with a flexible sampling vessel (spoon) that can be operated either pneumatically or manually. The spoon sampler is perfectly suitable for installations in downpipes. Even poor-flowing products can easily be sampled and filled in various sample vessels.

During the sample process with the HECHT spoon sampler, the empty spoon is inserted in the vertical product flow. A previously defined amount of product can now be collected with the spoon. Following, the filled spoon draws back into the sampling case, rotates 180° and drops the sample product into a discharge nozzle or a collecting tank. A special sealing unit protects the guidance for the longitudinal movement as well as for the rotation.

- During the sampling process, the sampler does not interfere with the product flow

- By means of a small knocker it is possible to even discharge poor-flowing products from the flexible sampling vessel (spoon).

- Sealed product filling pipe with flexible cuff and end seal

- Easy to dismantle (Tri-Clamps) and easy to clean

- Discharge into various sampling vessels (for example bottles); Connection to a sampling magazine or a sample connector with endless liner is possible

Vacuum samplers

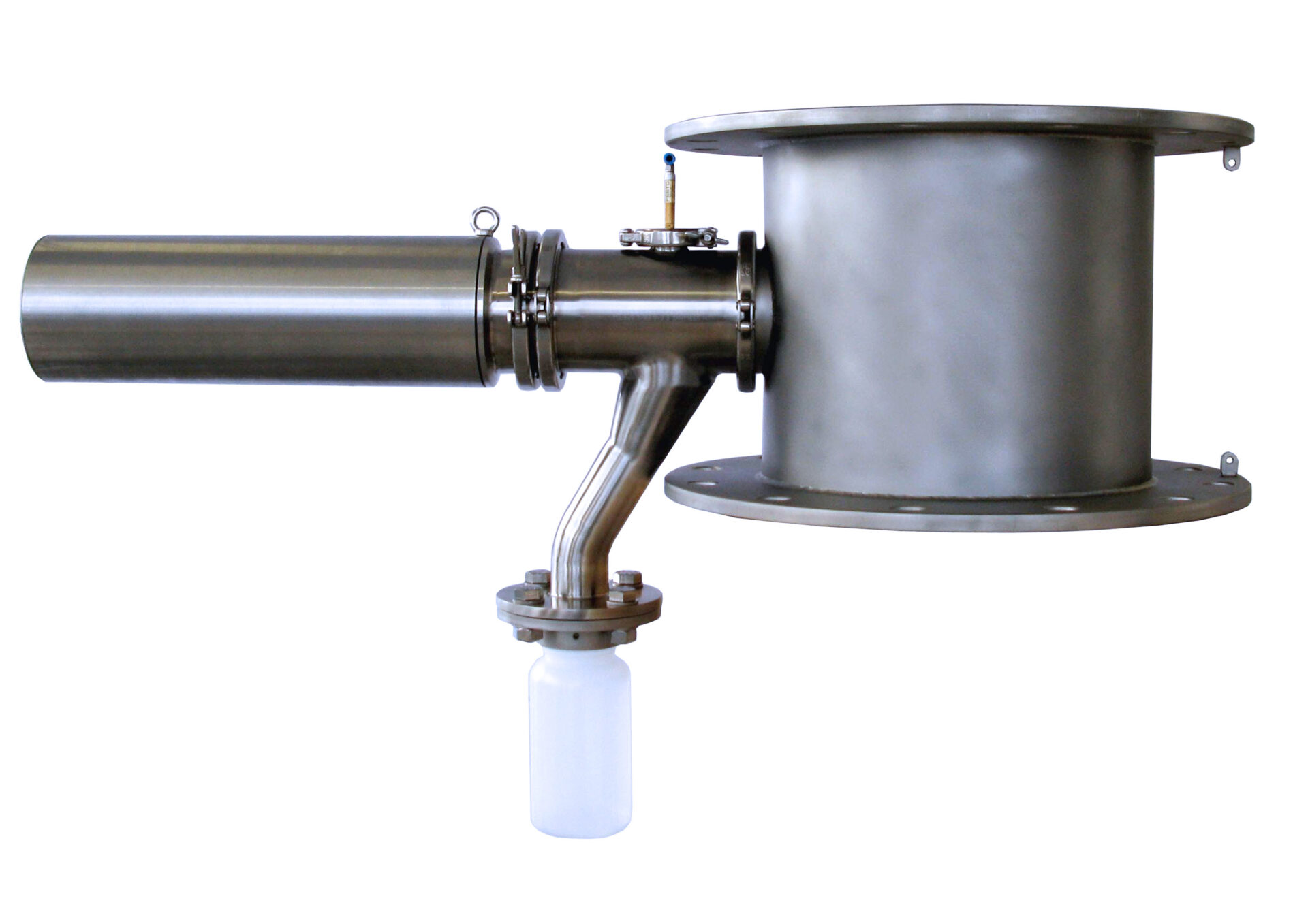

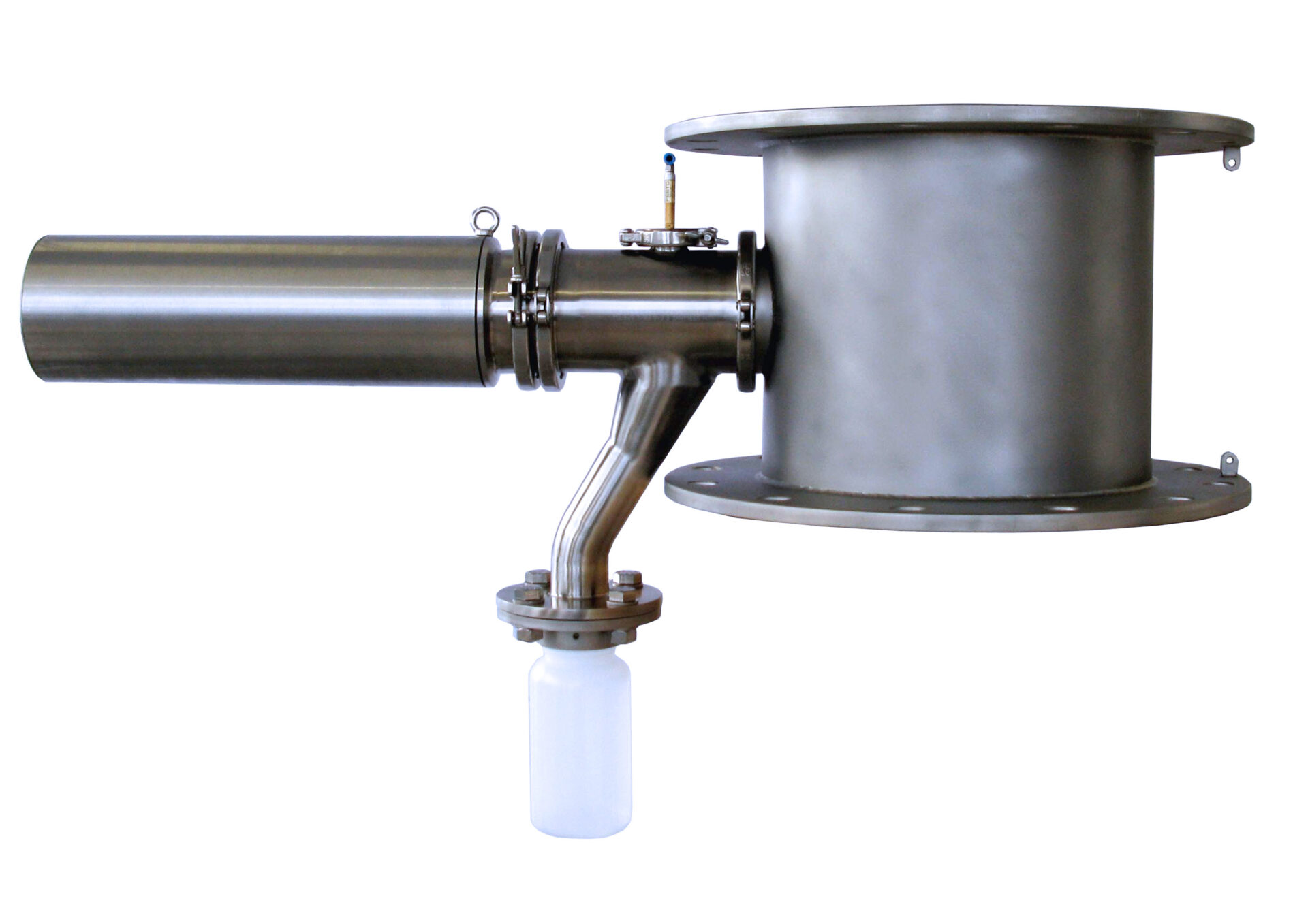

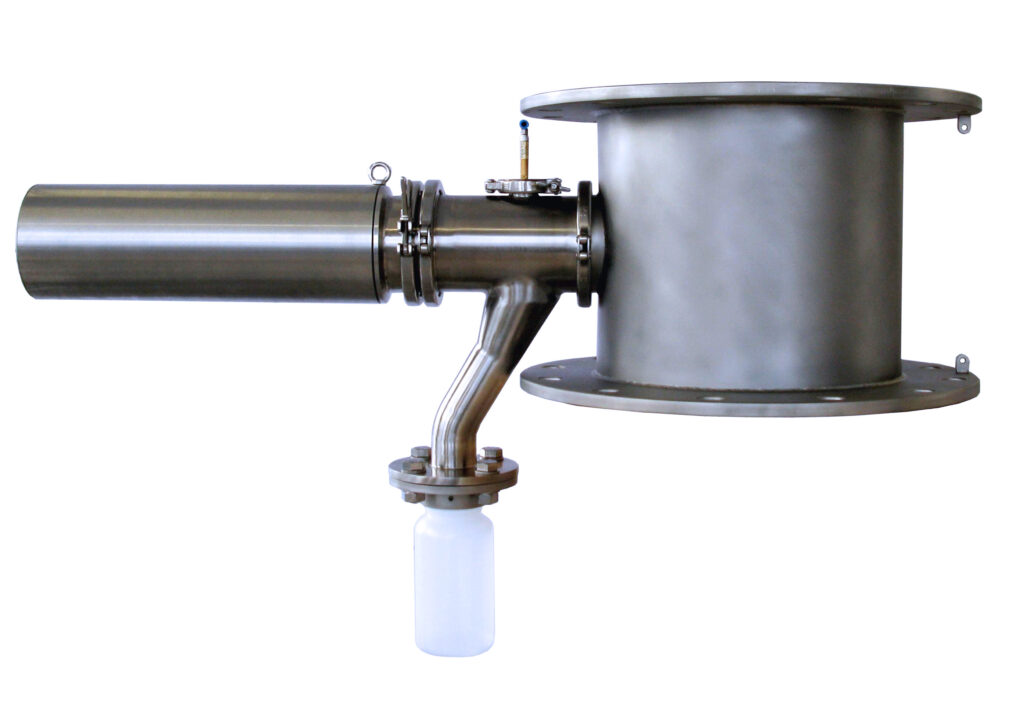

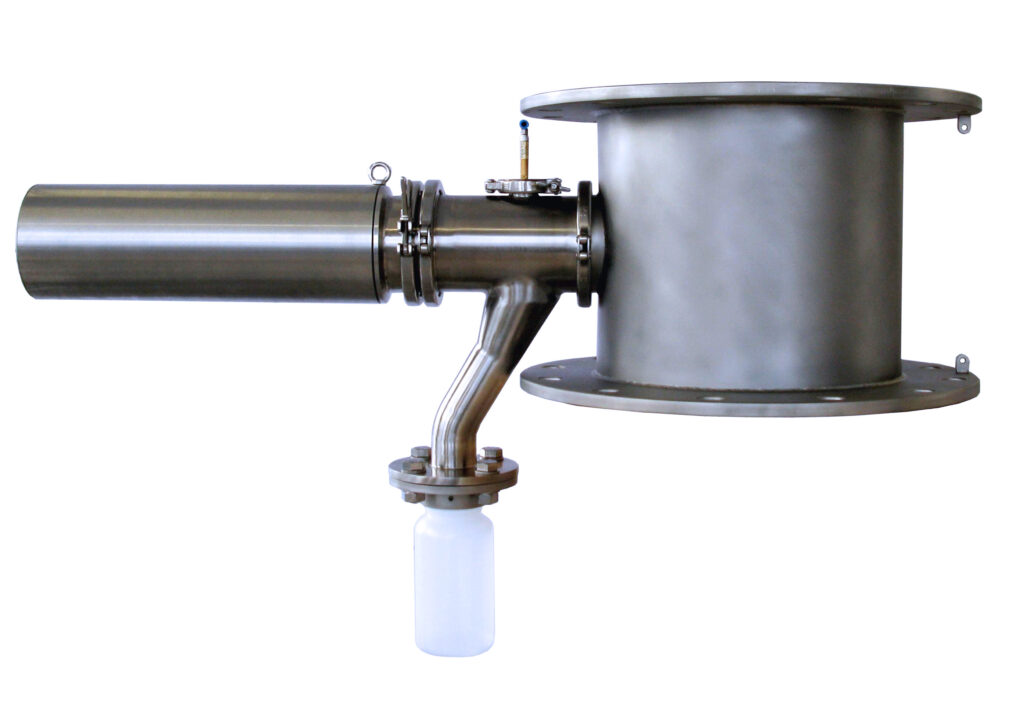

The HECHT Vacuum Sampler is ideally suited for closed and automated inline-sampling of powders and granulated materials from a product column. The special design for flush-wall-installation was recently patented: Due to its dead-space-free structure, the vacuum sampler neither contains mechanical parts protruding into the production flow, nor any hidden angles, which could complicate a thorough cleaning. Therefore, it is ideally suitable for poor flowing products and high-level hygienic- and Containment applications.

The pneumatic swivel drive opens the sealing valve via rotation (max. 180°) By means of a vacuum function, the product is aspired from the product column. An integrated ring filter avoids product loss in the vacuum pump. As soon as the defined amount is collected in the glass bottle, the ring filter is cleaned with a pressure impulse and the sealing valve closes.

Optional: Additional (Glove-) Box for Containment applications, shut-off devices to seal the sampler and avoid trickling when no bottle is attached; Expandable with sampling magazine for up to 24 samples or with a collector with endless liner.

- Sampling process flexibly adjustable due to different sizes of the sealing valve, the opening degree and the opening time

- Vacuum-tight and pressure resistant (up to 2,0 bar)

- Production flow is permanently free of mechanic parts

- Easy Cleaning

- Fast and simple dismantling due to Tri-Clamp connections

- Single components are easy to clean manually; wet cleaning is possible

- Dead-space-free construction simplifies the cleaning considerably

- Sampling is possible from blenders, dryers, pressure vessels and stirring tanks

Containment Sampling Port CPP

The HECHT Containment Sampling Port CPP has been designed for sampling under Containment conditions up to OEB 5. The sample is filled into wide-mouth bottles and can be visually checked until the desired filling level is reached. The filled bottle is removed via the endless liner. The Containment Sample Port can be easily combined with all common Hecht samplers like the sled or the screw samplers.

- Unique system – patent pending

- Sampling under Containment conditions

- Easy handling – no control system or other media required

- Optional: WIP Cleaning

- Combinable with all HECHT samplers