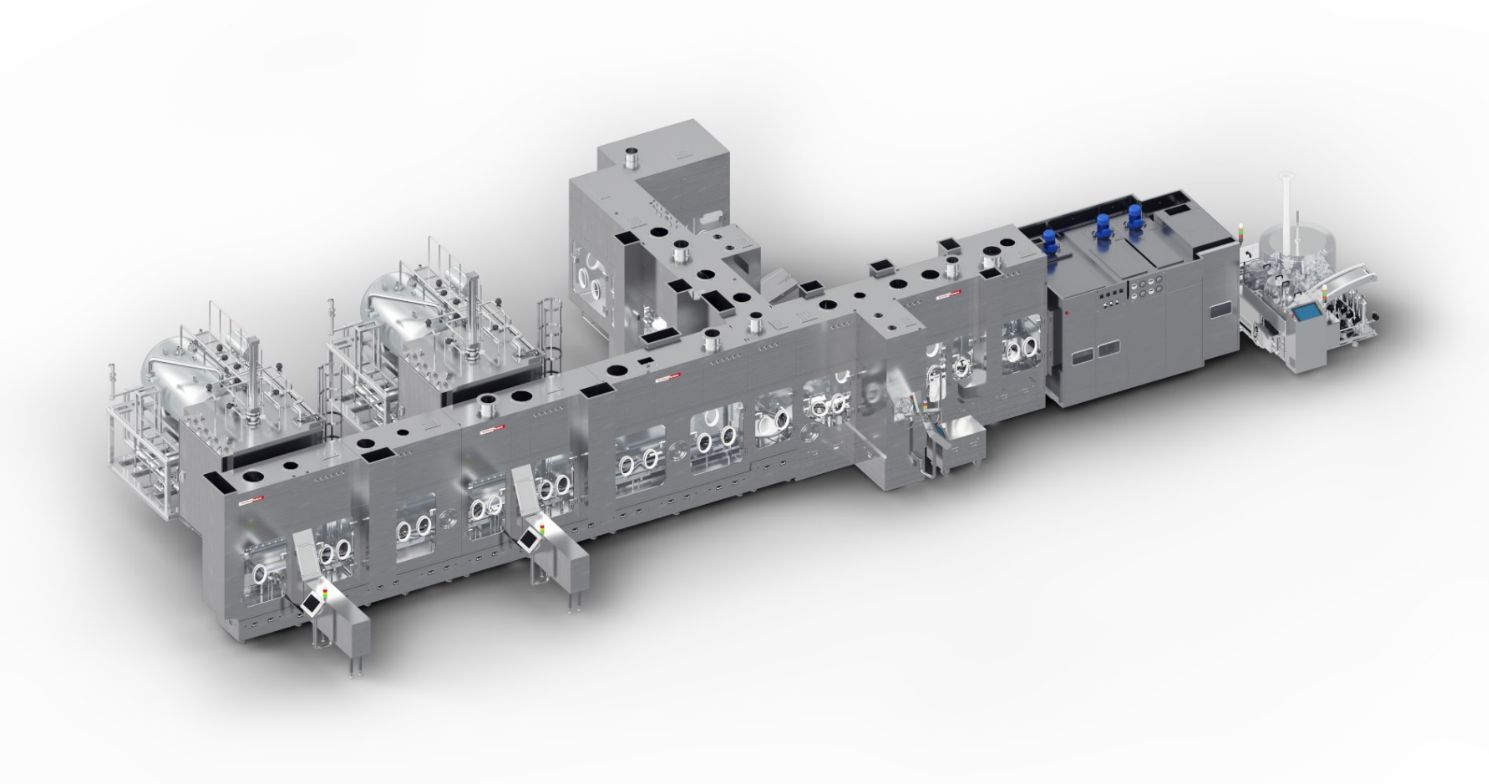

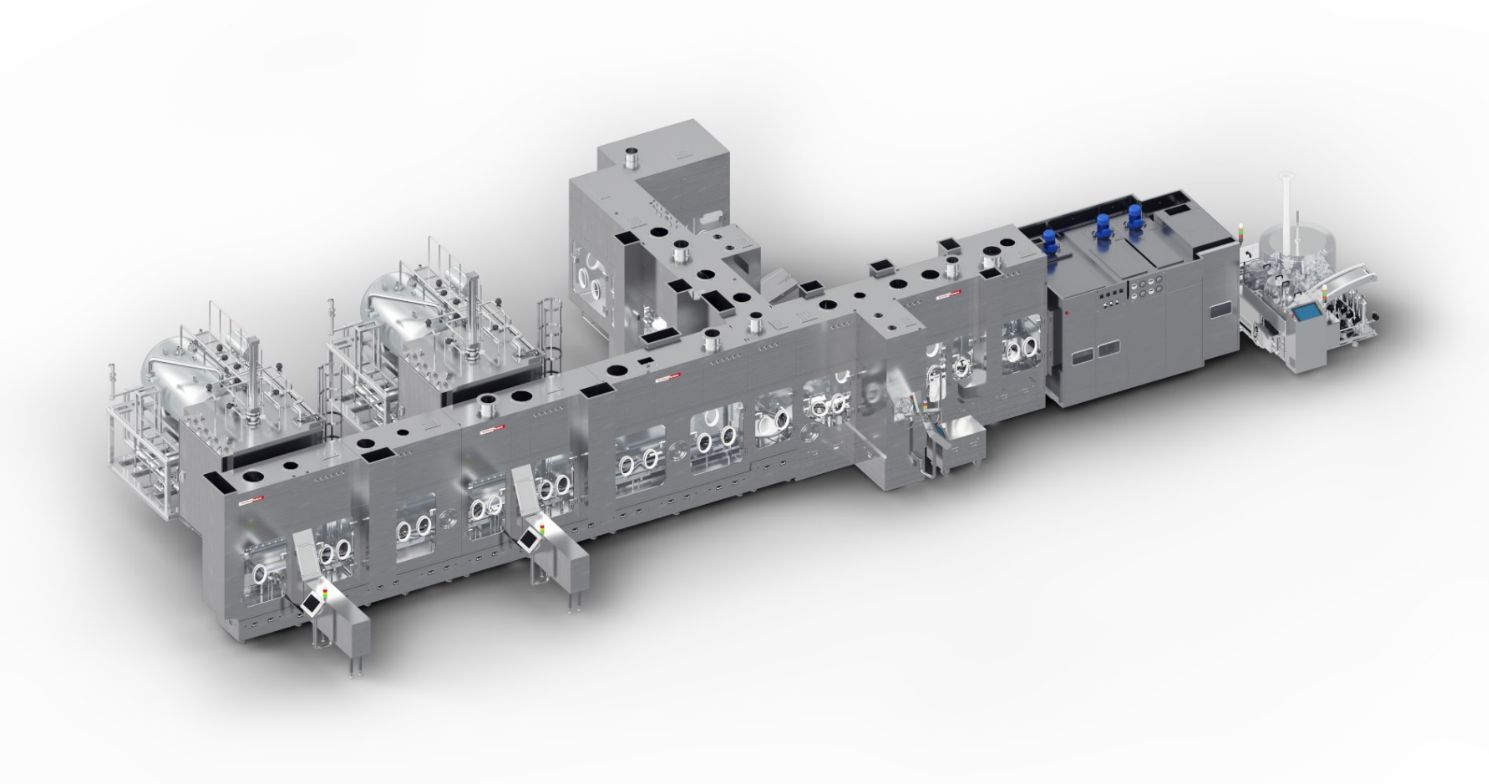

Tofflon Production Lyophilisers epitomize efficiency and innovation in the pharmaceutical and biotechnology sectors. Our robustly designed lyophilisers offer scalability and advanced controls, ensuring consistent quality. Featuring cutting-edge freeze-drying technology, they maximize production capacity while upholding safety and reliability. Tofflon not only provides superior equipment but also a commitment to precision and excellence in large-scale lyophilisation, coupled with the industry’s shortest delivery times and an unbeaten price-to-quality ratio.

Fastest delivery times

Tofflon Production Lyophilisers set the standard in the pharmaceutical and biotechnology industries, combining top-tier freeze-drying technology with unmatched efficiency. Our equipment guarantees superior performance and reliability, ensuring the best price-to-quality ratio. Tofflon stands out for its industry-leading short delivery times, exemplifying commitment to customer satisfaction and excellence.

In-Process Quality Control

In our commitment to in-process quality control, we meticulously conduct a variety of critical tests and validations, including the Shelves Temperature Uniformity Test, SIP (Sterilization in Place) Temperature Distribution Test, CPI (Critical Process Indicator) Validation, and Filter Integrity Test (WIT – Water Intrusion Test), ensuring the highest standards of reliability and efficiency in our processes.”

Yan Shen

Project Manager

“We will work with your team to choose the best products and specifications for your requirements. We can handle everything from the first phone call to installation.”

Call: + 33 6 31 55 95 79

Email: [email protected]

Production LYO-8 m²

Refrigeration System

- Modulardesign to achieve reliable and high efficiency production.

- Advanced pipeline process technology prohibits leaks.

- World-class refrigeration units ensure reliability with long service life.

- Each compressor has an independent circuit to cool shelves or condenser.

- Safety protection for compressors in high pressure, low pressure, motor overheat,differential oil pressure, unstable current, short circuit,lacking phase and cooling water flow, etc.

- Environment friendly HFC refrigerant:free of CFC and HCFC.

- Vibration absorbers to reduce vibration and noise.

- The flow rate of refrigerant is controlled by an expansion valve to achieve the precise temperature.

- Compressor: Copeland®,Bitzer® or Kobelco®,Mycom®.

| Model | 7,5 m2 | 10 m2 | 13 m2 | 15 m2 | 20 m2 |

|---|---|---|---|---|---|

| Usable Shelf Area m2 | 7,56 | 9,72 | 12,96 | 14,40 | 19,73 |

| Ice Capacity kg | 150 | 200 | 250 | 300 | 400 |

| Vials Capacity (22mm-10ml) nr | 17 100 | 22 000 | 29 400 | 32 700 | 44 800 |

| Vials Capacity (16mm-5ml) nr | 32 400 | 41 700 | 55 600 | 61 800 | 84 700 |

| Shelf Dimensions (L x W ) | 1200 x 900 | 1200 x 900 | 1200 x 900 | 1200 x 1200 | 1200 x 1200 |

| Nr of shelves | 7+1 | 9+1 | 9+1 | 10 + 1 | 11 + 1 |

| Shelf Spacing | 100 | 100 | 100 | 100 | 100 |

| Power Supply kW | 54 | 66 | 85 | 85 | 117 |

| Cooling Water m3/hr | 16 | 20 | 24 | 24 | 34 |

| Overall Dimension (L x W x H) | 4700 x 2300 x 3400 | 5200 x 2200 x 3800 | 6500 x 2300 x 3900 | 6500 x 2300 x 3900 | 7300 x 3000 x 4200 |

| Approximate Weight (ton) | 8,5 | 10 | 12,5 | 13 | 17,5 |