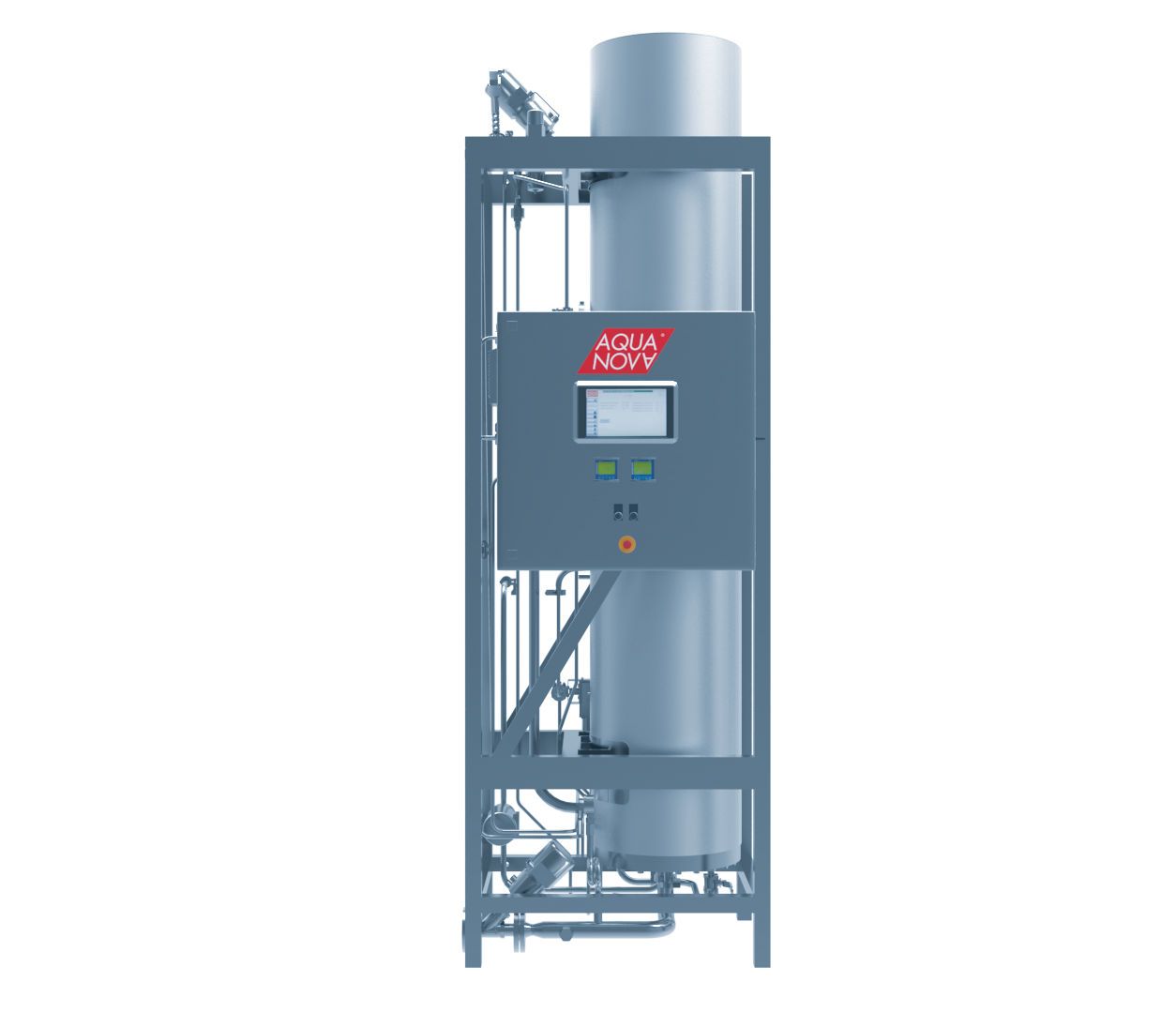

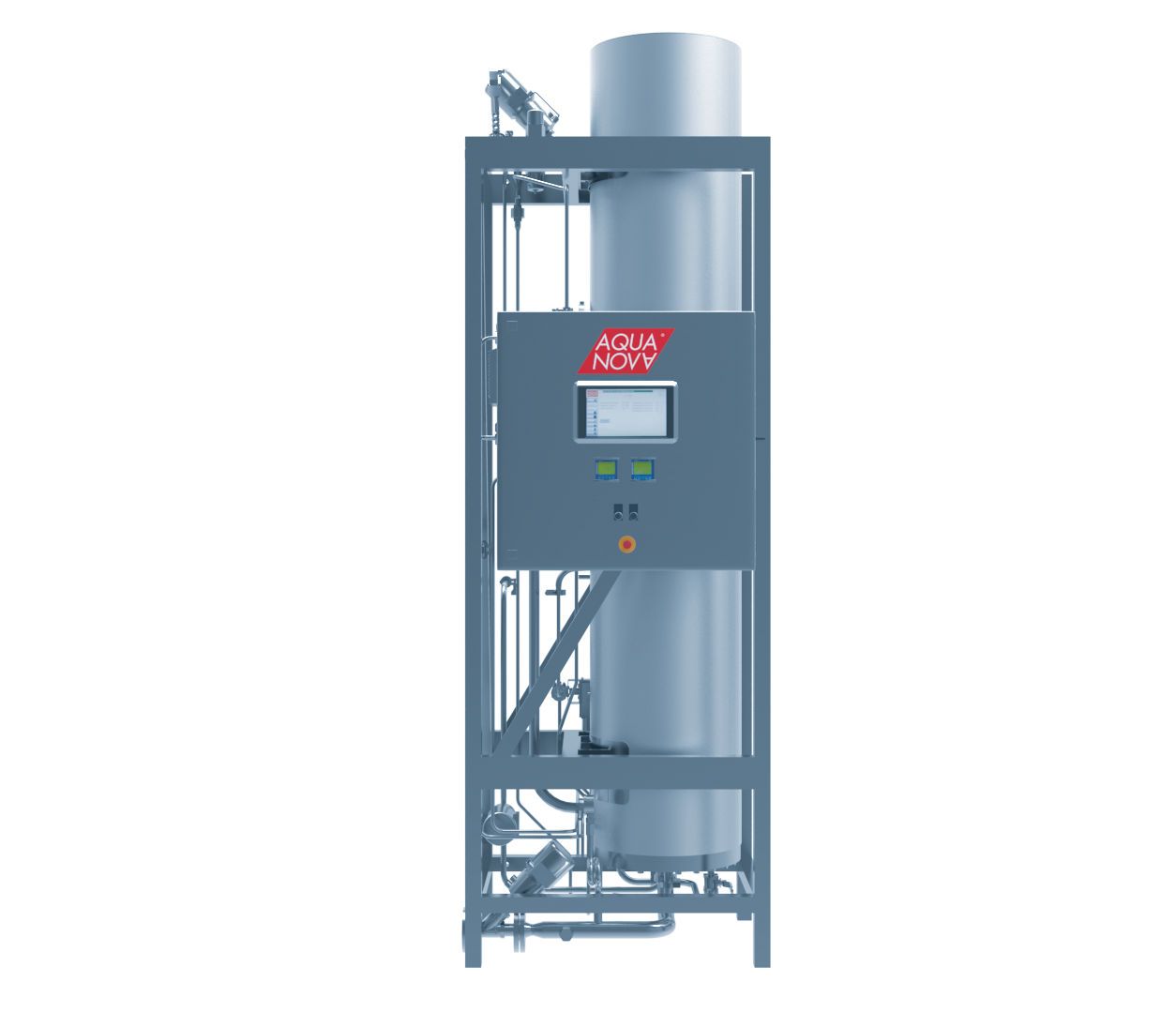

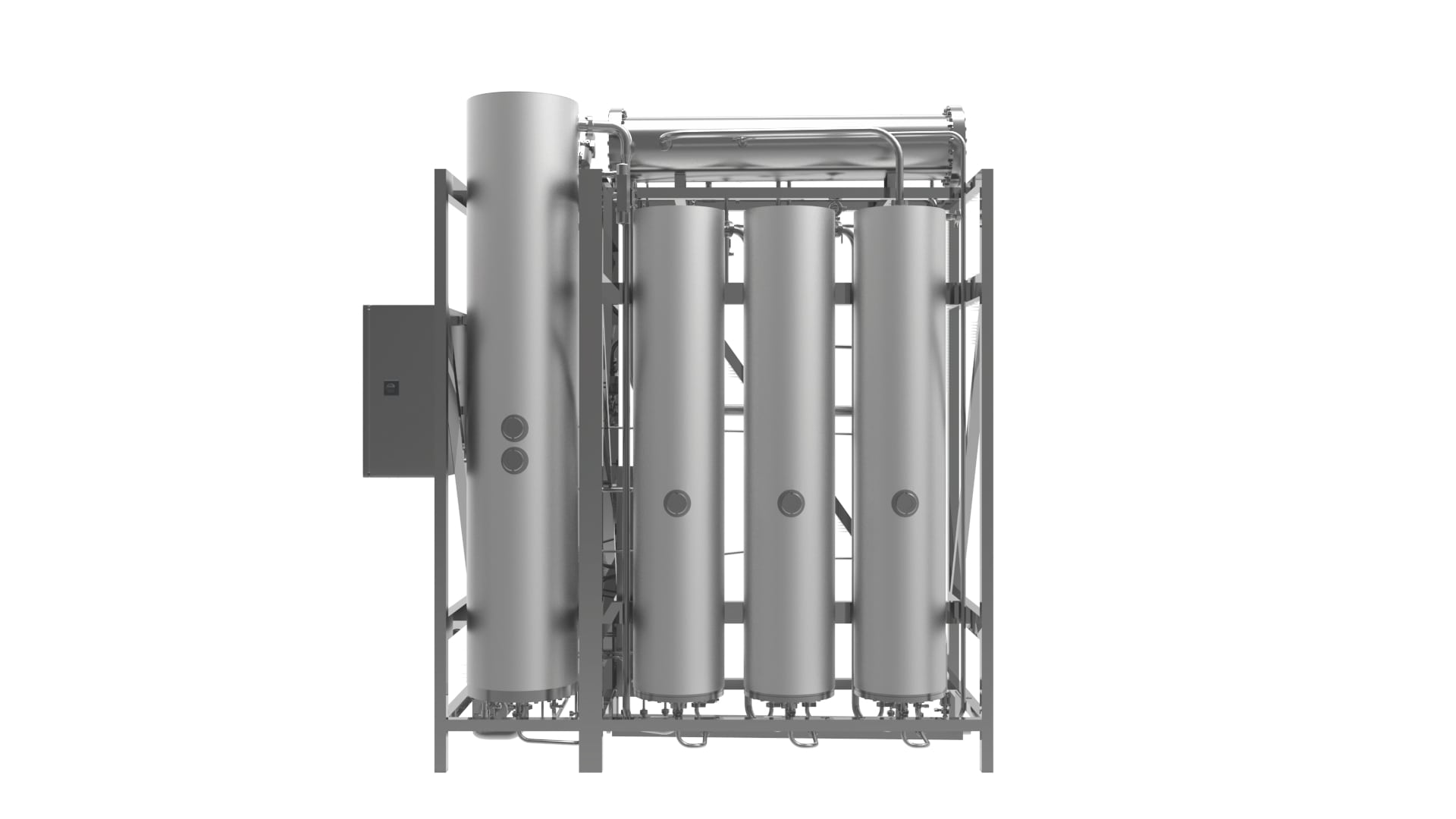

Steam Heated Single Effect Still AQUA-NOVA S-50 / 150-C produces 50 to 150 lt/h of pyrogen free distillate Water For Injection and or Pure Steam of the same quality, from RO or deionised feed water of good quality. E-50-C produces 50 lt/h of distillate or 50 kg/h of steam.

The column is designed as a pressure vessel and can be used as a Pure Steam Generator to sterilise external systems and equipment. The Generator function is optional.

Discover AQUA-NOVA S-50/I50-C

Designed as a pressure vessel, it doubles as a Pure Steam Generator for external sterilisation. Experience unparalleled separation with its baffle section, low steam velocities, and cyclone separation. Fully automatic or semi-automatic, it includes all necessary valves tailored to your needs. An optional conductivity meter ensures consistent quality, automatically diverting sub-standard distillate. The still, housed in a stainless steel frame, features easy access, stationary gaskets, and a spill-free drain collector. With spiral heat exchangers, easy maintenance, and cGMP-compliant condenser design, the AQUA-NOVA S-E 50-C is the epitome of efficiency and reliability. Enhance your operations with this versatile and user-friendly water and steam solution!

Enjoy 50 liters/hour of high-quality distillate or steam.

Your Ultimate Solution for Pure Water and Steam Generation! This advanced system effortlessly delivers 50-150 liters/hour of pyrogen-free Water for Injection or Pure Steam from RO or deionised feed water.

Sebastian Bjorksten

Managing Director Sofinn UK Ltd

“We will work with your team to select the best products and specifications that meet your needs. We can handle everything from your first phone call to the installation.”

Call: +44 7539 432 772

Email: [email protected]

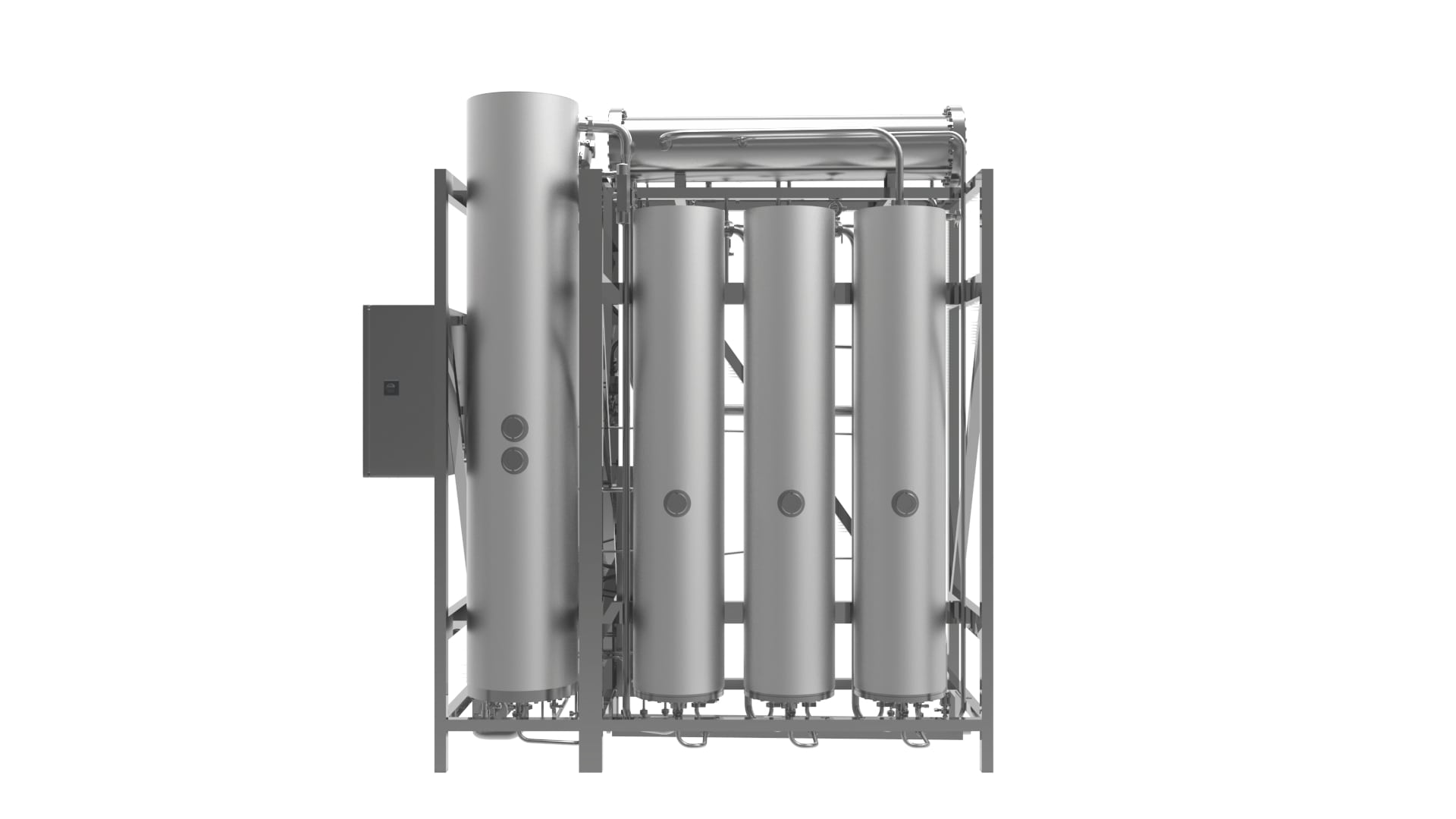

SINGLE EFFECT STILL, Steam Heated, S-50/150-C

All parts in contact with the distillate are made of acid proof stainless steels, AlSI 316L or equal Swedish st.st. quality.

O-rings and gaskets in contact with the distillate or clean stem are made of FDA approved pharmaceutical quality. The frame is made of stainless steel.

| Production / Consumption | Production / Consumption | Production / Consumption | |

|---|---|---|---|

| Distillate, 95°C | 60 l/h | 100 l/h | 150 L/h |

| Feed Water 15°C 3-6 bar g | 72 l/h | 120 l/h | 180 l/h |

| Cooling Water 15°C, 2 bar g | 300 l/h | 600 l/h | 900 l/h |

| Plant Steam | 1 bar g, 121°C: 72 kg/h | 2 bar g, 134°C: 120 kg/h | 3 bar g, 152°C: 180 kg/h |

| Electricity | 35 kw | 35 kw | 35 kW |