The accuracy of dosing- and weighing units for bulk material handling are crucial factors for the overall result. Hecht can put together the right weighing and dosing concept according to the client’s needs.

The important dosing and weighing concept

Sometimes, a precise measuring only may not be enough and it is reasonable to take the following points into consideration:

- maximum product protection

- dead-space-free design

- residue-free discharging

- simple handling

- easy-to-clean surfaces

- hygienic design

At HECHT we can

At HECHT there are many options for dosing and the HECHT powder experts are there to help the customer choose the right technology and methods depending on the accuracy, the cleanability requirements and the powder characteristics.

Helena Artama

Application Specialist Sterilisation and Powder Handling

“Let’s get in contact with the HECHT expert in BigBag Discharge. Together we will find the optimal connection system and select the right options for your application.”

+ 33 (0)6 83 28 95 43

Rotary Valves

The rotary feeder in easy-to-clean design from HECHT is especially used for frequent product changes. It is a dosing device for various filling stations or loading point for screening machines, particularly for food or pharmaceutical applications. The particularly easy cleaning offers an enormous advantage with frequent product changes.

The rotor transfers a determined product quantity from the product inlet to the product outlet of the feeder and ensures a controlled and precise dosing. By adjusting the rotational velocity, the product flow can be controlled. A magnetic safety sensor prevents the rotor from driving after the lid is opened.

Dosing Valve

Dosing valves are a simple and efficient solution for a smooth discharging of bulk solids like powders or granulates. A smooth flow rate is generated due to the vibration and the bulk material can flow freely. Product bridges, crystalline compounds can be loosened and a correct dosing is guaranteed.

- Mechanically driven high-frequency vibration and dosing valve

- Simple regulation for a continuous product flow

- Very accurate fine dosing

- Shaft with multiple bearings

- One-piece, gap-free connections

- Reduction of incrustations

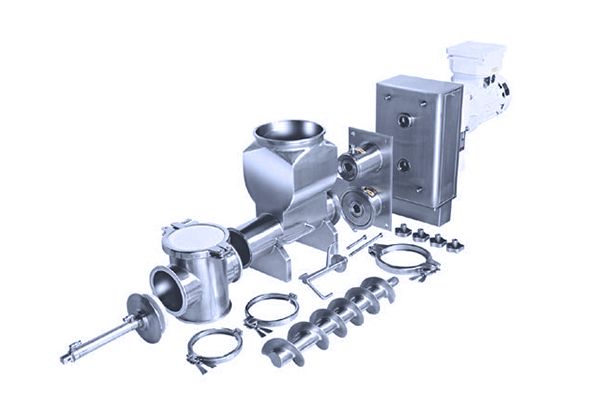

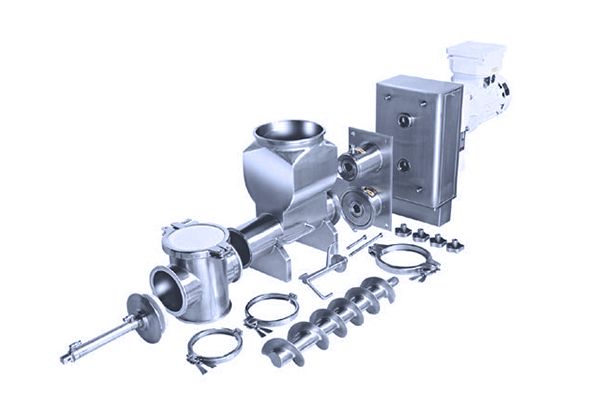

Dosing Screws

Depending on the bulk material in use and the respective application, our dosing screws can be used either volumetrically or gravimetrically. Substances and granulates with good flow behaviour can therefore be volumetrically dosed. The necessary flow rate can easily be regulated by the rotation speed of the screw. According to the rotation number the dosing capacity depends on the flow rate that is conveyed per time unit.

For loss-in-weight dosing according to a fixed, documentable default nominal value, a gravimetric dosing is recommended in combination with a weighing and control device. Here, the mass flow control and measuring is done via weight control.

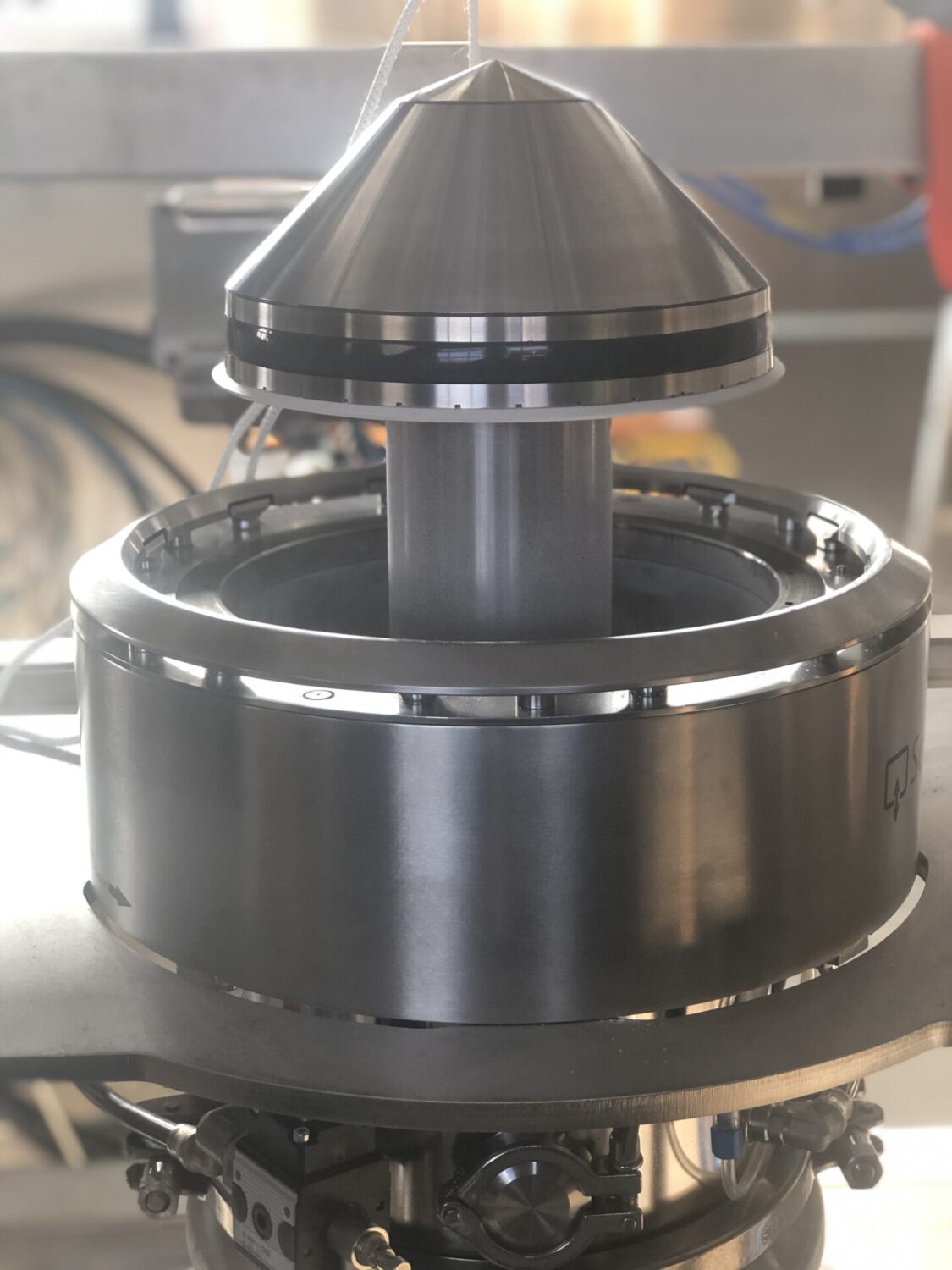

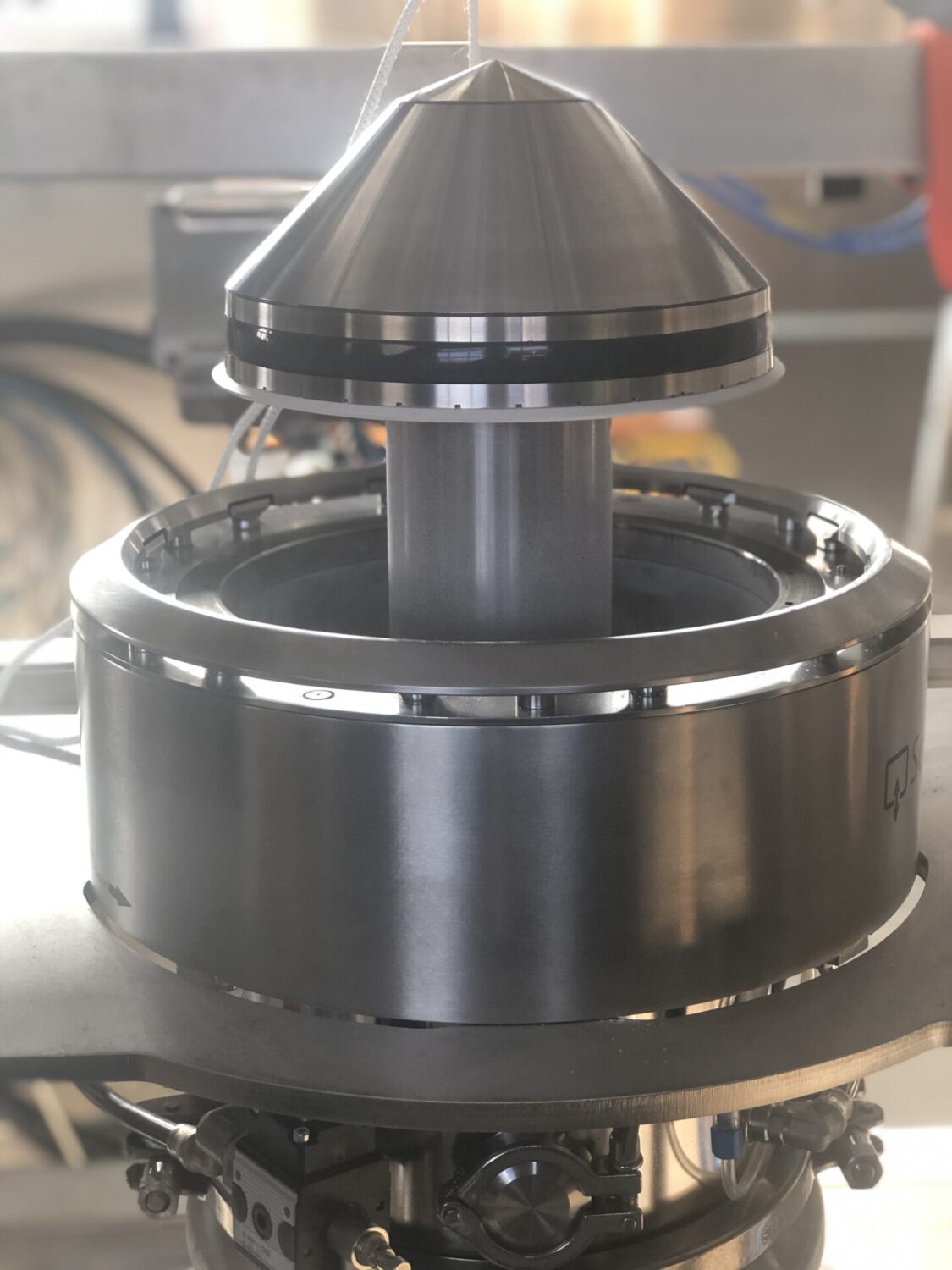

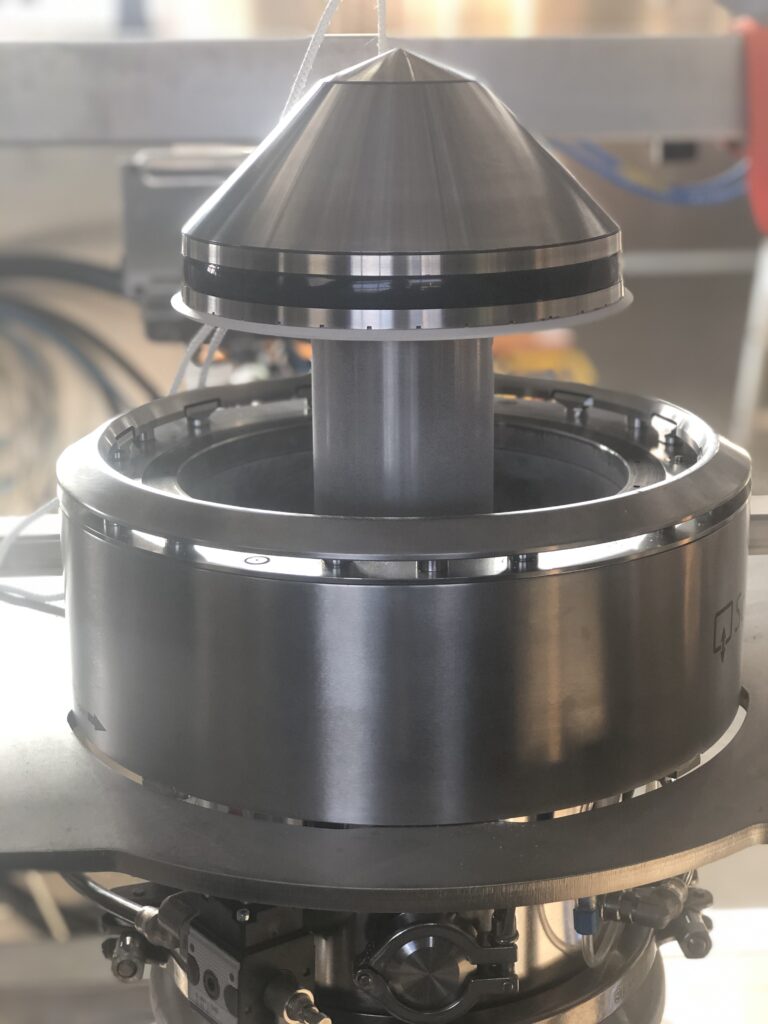

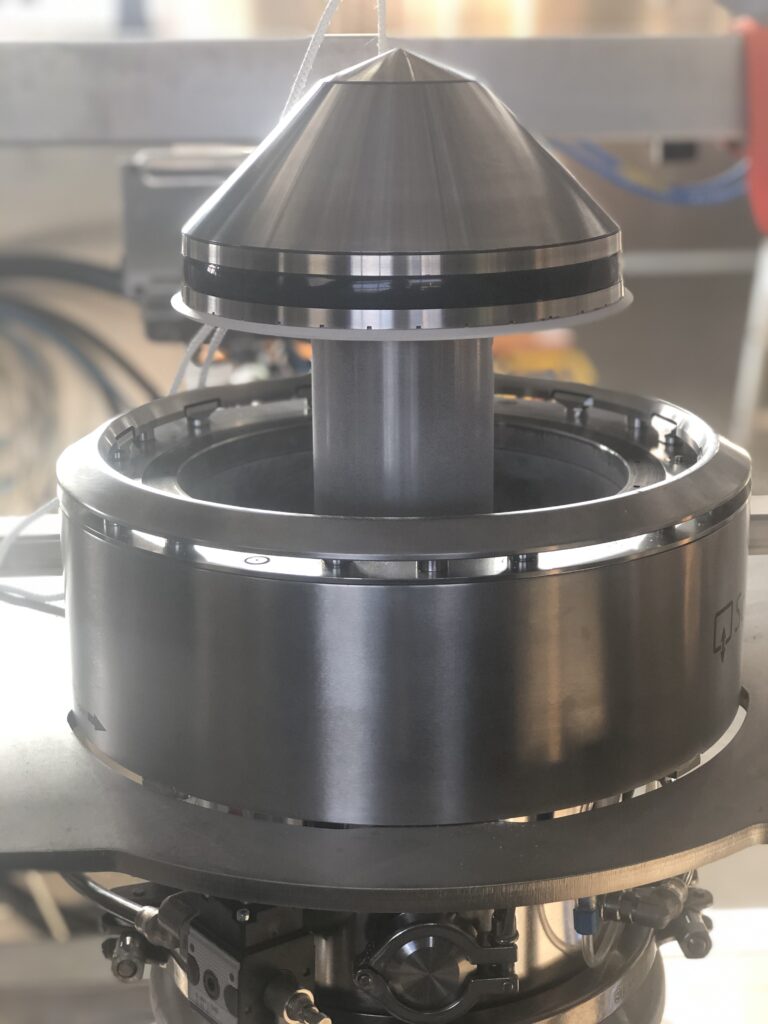

SoliValve Split Cone Technology

Unlike any other solution for powder handling on the market, the SoliValve® technology is versatile, reliable and guarantees outstanding results and performance in terms of containment (OEB5), dosing accuracy (+/-1g) and complete automation.

Only the SoliValve® technology allows to fill or discharge completely or partly FIBCs, Rigid IBCs, drums and bags via the same docking unit thanks to the universal Passive-SoliValve® design.

The SoliValve® is compatible with all type of recipients from Rigid IBC, FIBC to drums and is the only Cone Valve system equipped with the patented fluidisation feature that allows to blow air or nitrogen inside the recipient to help discharge difficult flowing powder, break bridges and avoid segregation. The SoliValve® system is fully automated. No manual operations are needed anymore to connect/disconnect the recipient. Thanks to a state of the art dosing algorithm, a millimeter accurate positioning of the opening and an internal high frequency vibrator, the SoliValve® allows very precise and repeatable dosing (precision of 1% (even 0.5% with SoliValve®100) can be achieved depending on the scale resolution. The Passive-SoliValve® being made of injected polymer, it is very cost efficient, and allows single usage of FIBC instead of expensive RIBC.