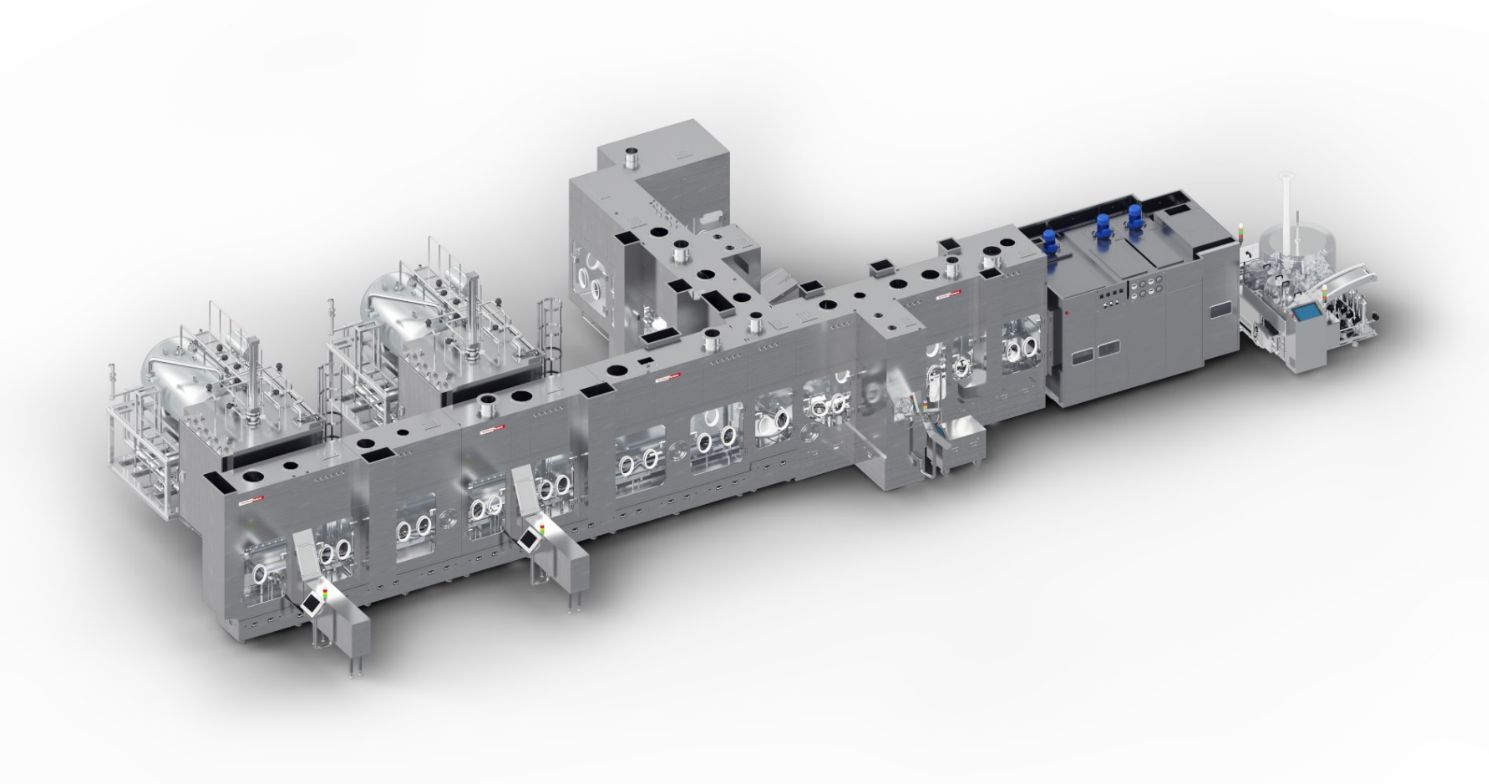

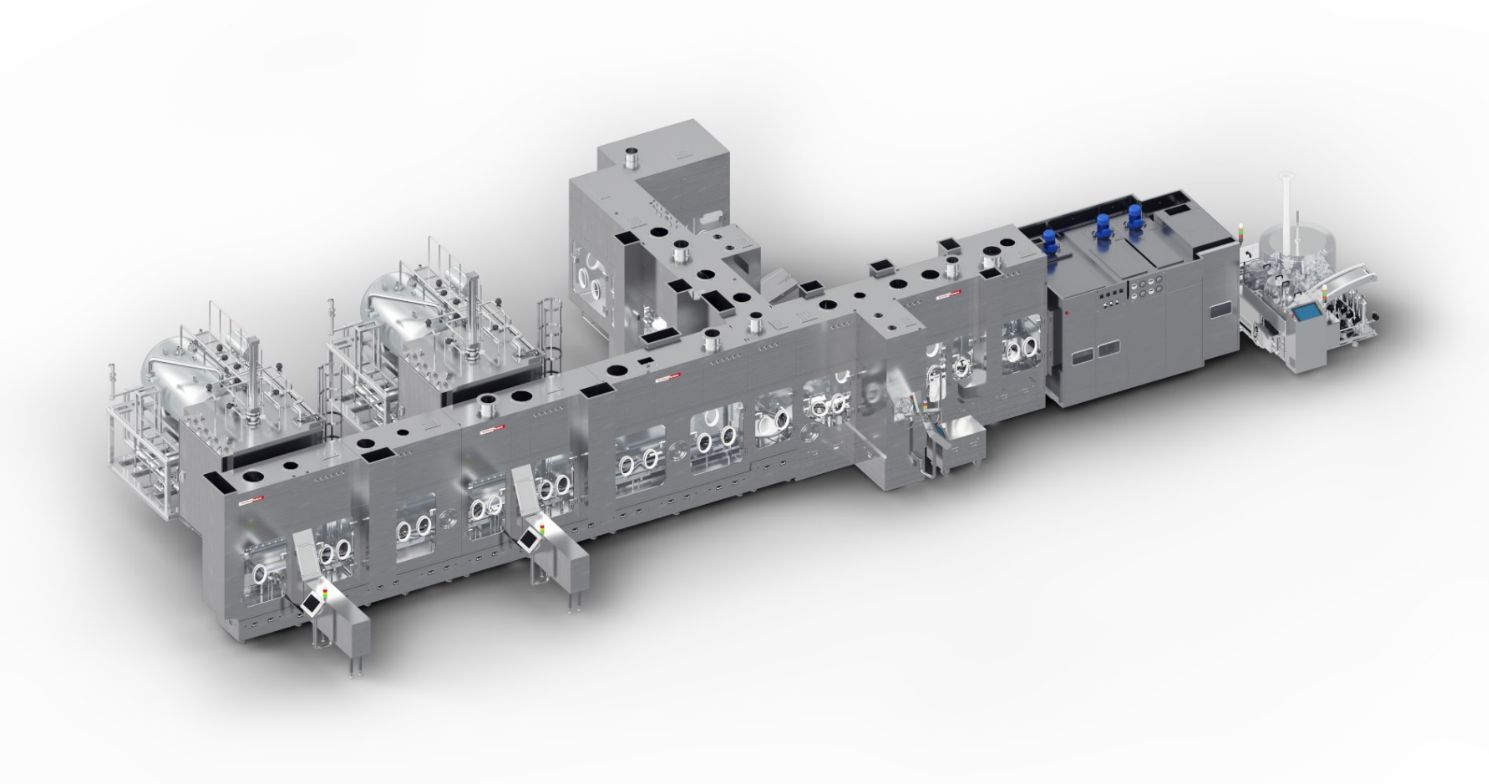

Tofflon sterilisation tunnels are crucial equipment in the pharmaceutical manufacturing process, particularly for ensuring the sterility of vials before filling.

Designed to Sterilise

The tunnel is designed to sterilise and dehydrogenise the ampoules by a laminar flow of hot air with continuous process. Grade A is assured in all the areas above the openings of the ampoules. Ampoules are trans-ported through the preheating zone, heating zone and cooling zone by a conveyor belt made of stainless steel wire mesh

In Process Quality Control

In our commitment to in-process quality control, we meticulously conduct a variety of critical tests and validations, including the Shelves Temperature Uniformity Test, SIP (Sterilisation in Place) Temperature Distribution Test, CPI (Critical Process Indicator) Validation, and Filter Integrity Test (WIT – Water Intrusion Test), ensuring the highest standards of reliability and efficiency in our processes.

Yan Shen

Project Manager

“We will work with your team to choose the best products and specifications for your requirements. We can handle everything from the first phone call to installation.”

Call: + 33 6 31 55 95 79

Email: [email protected]

Vial Sterilisation Tunnel

- Scientific calculation(>3Log), modular design and Independent air duct design.

- Negative pressure sealing for the HEPA.

- Flexible pressure zone concept for safe processes (Washing zone < Infeed zone<Heating zone> Cooling zone <Filling area).

- Validation ports for filter integrity test, particle counting and air velocity test.

- Power failure potection: backup power supply switch / compressed air cooling in the heating zone.

- Different working modes (Day mode / Night mode).

- Critical parameters of the process are continuously monitored and printed.

- Air-cooling type tunnel, no need chilled water.

- Self-cooling fan motor without extra cooling medium

| Model | FTV 01-10 | FTV 01-20 | FTV 01-30 | FTV 01-40 | FTV 01-50 |

|---|---|---|---|---|---|

| Belt width (mm) | 600 | 850 | 850 | 850 | 1 000 |

| Vial (ml) | 2-100 | 2-100 | 2-100 | 2-100 | 2-100 |

| Mechanical Output (vph) 10ml | 6 000 | 12 000 | 18 000 | 24 000 | 30 000 |

| Cooling water (m3/h) | 3 | 3 | 5 | 6 | 7 |

| Power Supply (kW) | 54 | 80 | 116 | 140 | 180 |

| Dimensions L x W x H (mm) | 2800 x 2100 x 2500 | 2800 x 2100 x 2500 | 4400 x 2400 x5500 | 5800 x 2400 x 2500 | 2800 x 2100 x 2500 |

| Weight (kg) | 3 000 | 3 500 | 4 500 | 5 500 | 7 000 |