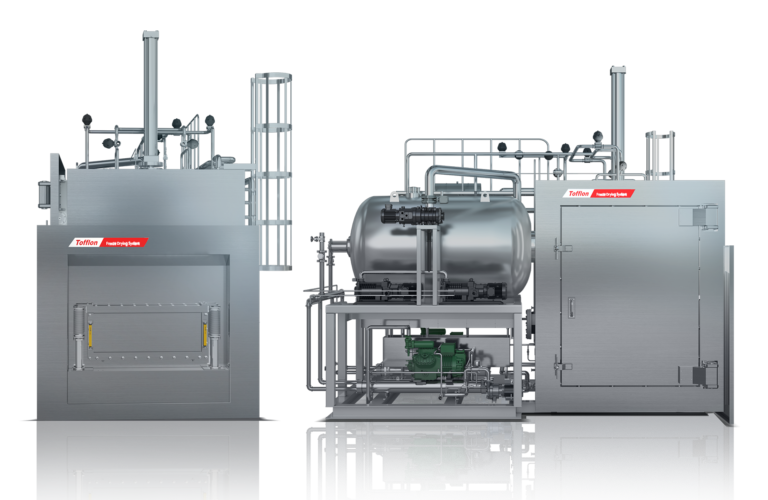

Effluent decontamination systems (EDS) play a crucial role in ensuring environmental safety, especially in the pharmaceutical industry. This white paper functions as a selection guide for the patented Pharmtec EDS, embodying cutting-edge design and functionality, with a focus on sterility and environmental protection.

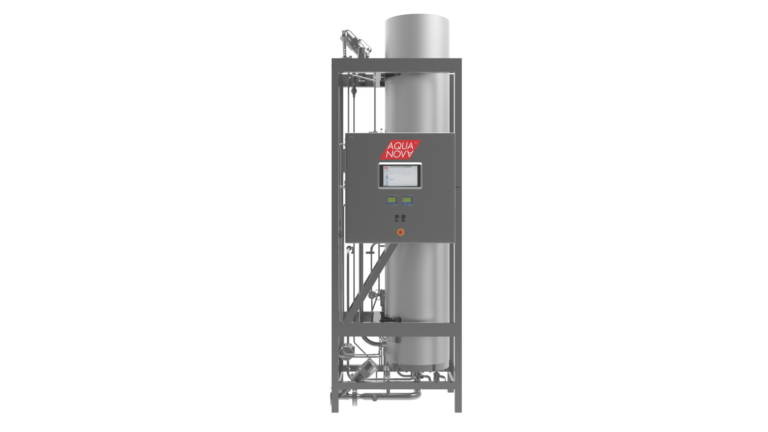

Aqua-Nova COMBI unit – Two in One

WFI and Pure Steam: two similar and yet different fluids

Simultaneous production is possible thanks to the unique Aqua-Nova technology. Here’s how!

Following strong interest