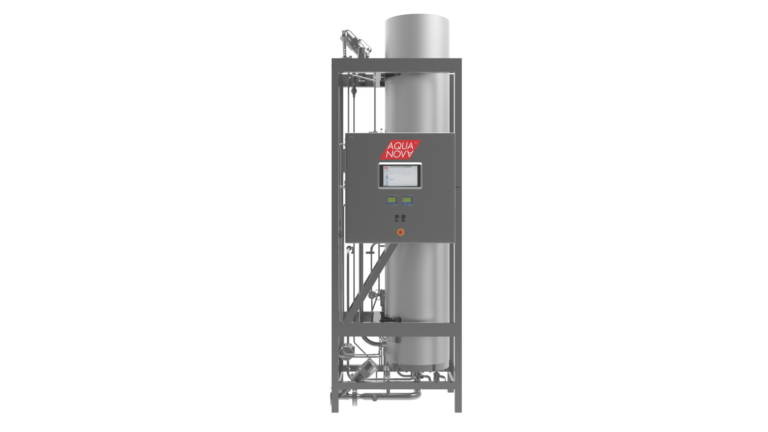

Pharmtec SA, a subsidiary of the Sofinn Group, is excited to announce a strategic cooperation agreement with Aqua-Nova AB of Sweden. This significant partnership will commence on November 1, 2023, marking a new era in the manufacturing, marketing, and selling of Aqua-Nova’s innovative water purification products.

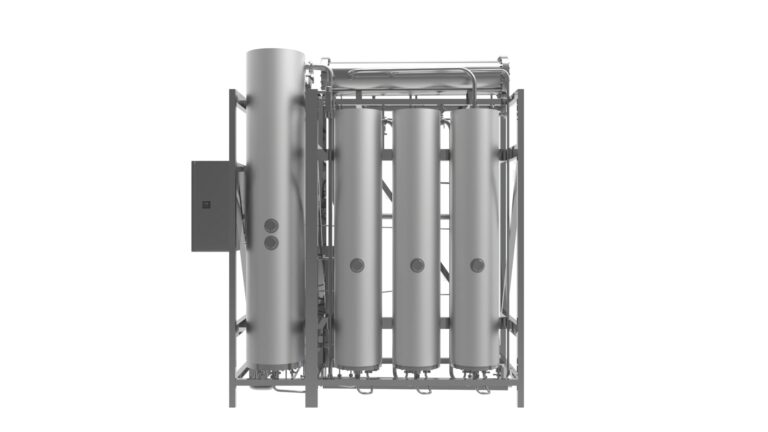

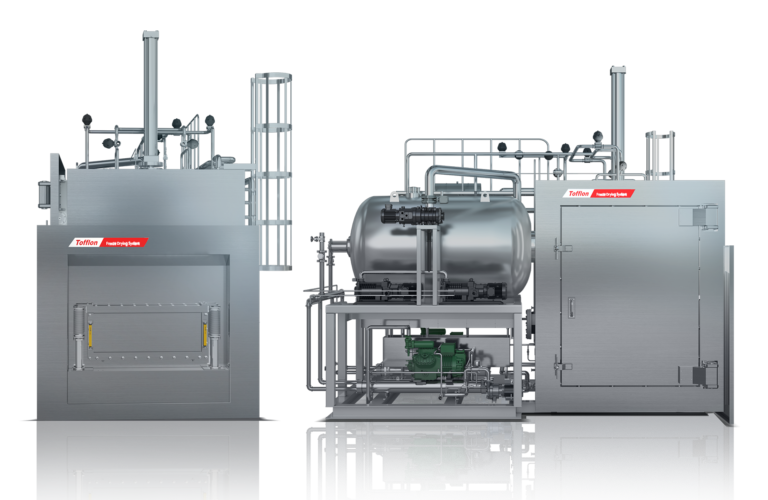

Aqua-Nova AB, known for its expertise in creating multiple effect water stills and pure steam generators, holds the ownership of the Aqua-Nova brand. This collaboration with Pharmtec SA, an industry leader in hot water WFI products, hot sterilisation, and effluent decontamination solutions, is poised to redefine standards in the pharmaceutical industry.

The agreement signifies a deepening of the existing relationship between the two companies, where Pharmtec has already established itself as a pivotal contributor to Aqua-Nova’s growth and success as the brand’s exclusive agent in France. This new chapter in their partnership will further leverage Sofinnäs sales expertise, especially in the demanding international pharmaceutical sector.

As part of the agreement, Pharmtec SA will manufacture Aqua-Nova’s products, contributing to the brand’s expanding global footprint.

Gunnar Björkstén, owner of the Sofinn Group and joint majority owner of Aqua-Nova AB with Lennart Kärrberg, expressed his enthusiasm for this partnership. “This agreement represents a fusion of strengths. Combining Pharmtec’s sales prowess and Aqua-Nova’s innovative technology, we are set to make significant strides in the pharmaceutical industry,” he stated.