Since its founding in 1977, Pharmtec SA has been part of the Sofinn group. The group consists of several companies offering cutting-edge equipment for the pharmaceutical and biotechnological industries, including turnkey solutions for distillation, sterilisation, lyophilisation, effluent decontamination, washing, and filling.

The strength of a group lies in its ability to mobilise diverse skills, fostering innovation and excellence. This collaboration has allowed Pharmtec to explore new horizons, optimise its operations, and proactively respond to the changing needs of the industry for several years.

A broader market is part of a vision to expand into a larger market, where Sofinn and Pharmtec can capitalise on the extended resources and expertise of the group. Being part of the Sofinn Group, Pharmtec benefits from privileged access to a broader market, thus strengthening its presence and impact.

The Pharmtec brand will in the future be synonymous with the forefront in Effluent Decontamination as we will continue to develop our well known patented solutions for effluent Decontamination under the Pharmtec brand.

1976: Foundation of Sofinn SA to serve the French market with various Finnish high-tech equipment.

1977: Establishment of Finn-Aqua SA (now Pharmtec SA) to specialise in the market of water distillation for the pharmaceutical industry.

2021: Pharmtec opens a workshop in Normandy and delivers its first equipment, an Effluent Decontamination Station and a Duo System of two GVPs).

2022: The company renews its partnership with Tofflon, a world leader in lyophilisers, and becomes the exclusive representative of the brand in France and Finland.

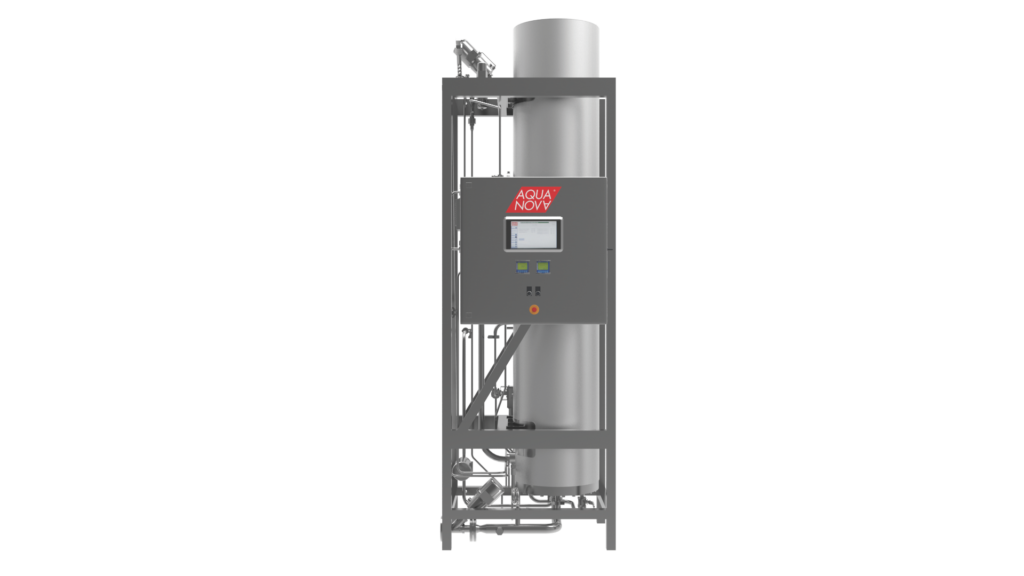

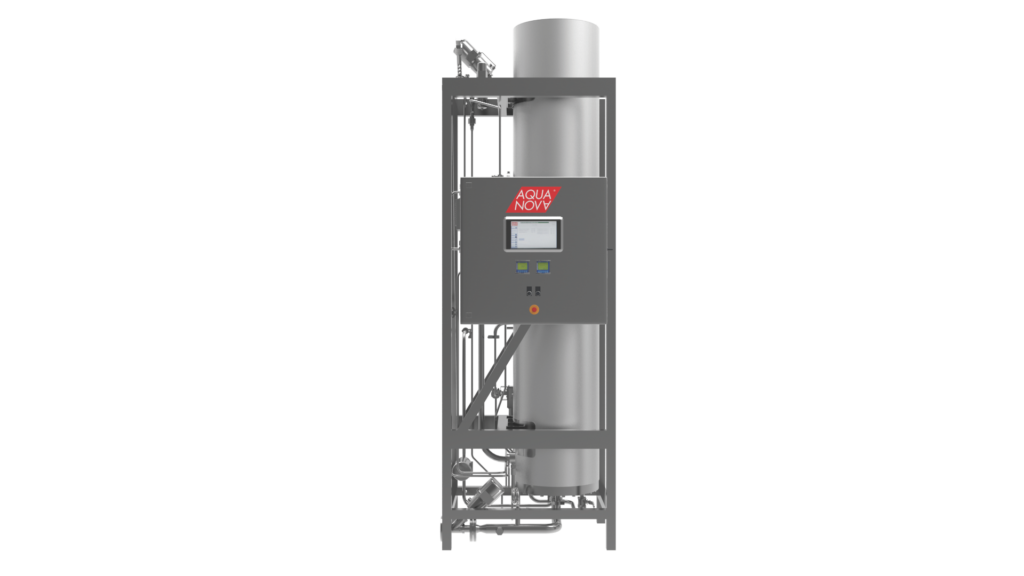

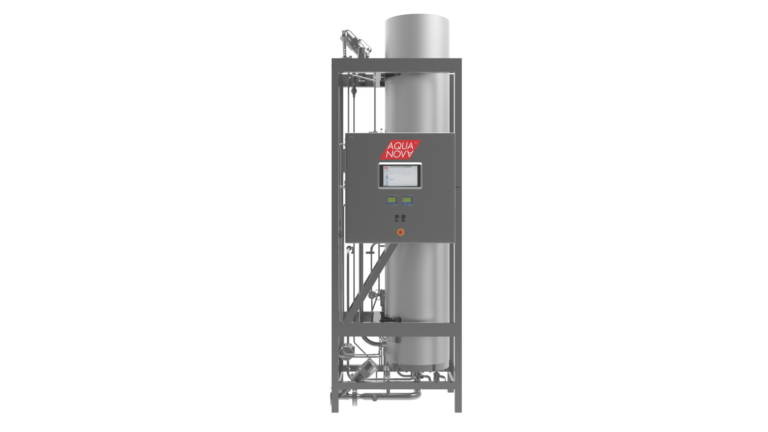

2023: Start of French manufacturing of Aqua-Nova equipment (Water Distillers for WFI, Pure Steam Generators, combi devices: 2 in 1) through manufacturing agreement with sister company Aqua-Nova

You will now find Pharmtec’s activities and news on this website. Pharmtec will continue to serve its customers in France and develop its products and services as before.

For more information:

Mats Mickos

Managing Director

Pharmtec SA

[email protected]

+ 33 6 77 51 96 26