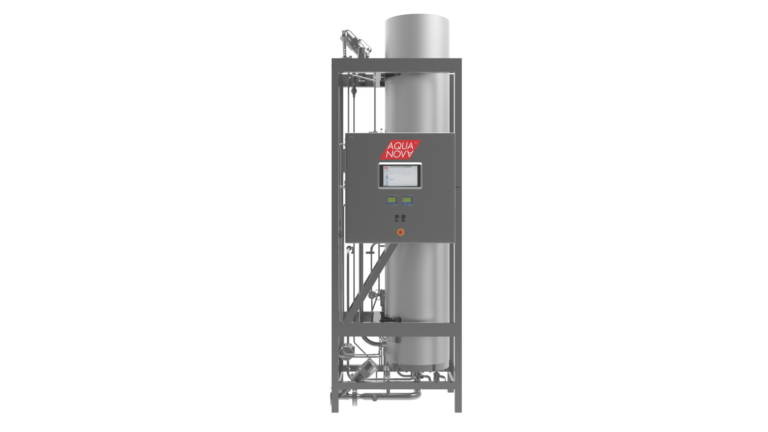

WFI Still and Pure Steam Generator in one unit”

WFI and Pure Steam: two similar and yet different fluids

Simultaneous production is possible thanks to the unique Aqua-Nova technology. Here’s how!

Following strong interest from our customers for combination units where Water For Injection and Pure Steam is generated simultaneously. AQUA-NOVA developed its first Combi unit in the mid 90s and whose first unit was delivered in 1995.

The special characteristics of Combi units are producing the required amount of WFI and simultaneously the amount of pure steam needed without affecting the production of distillate.