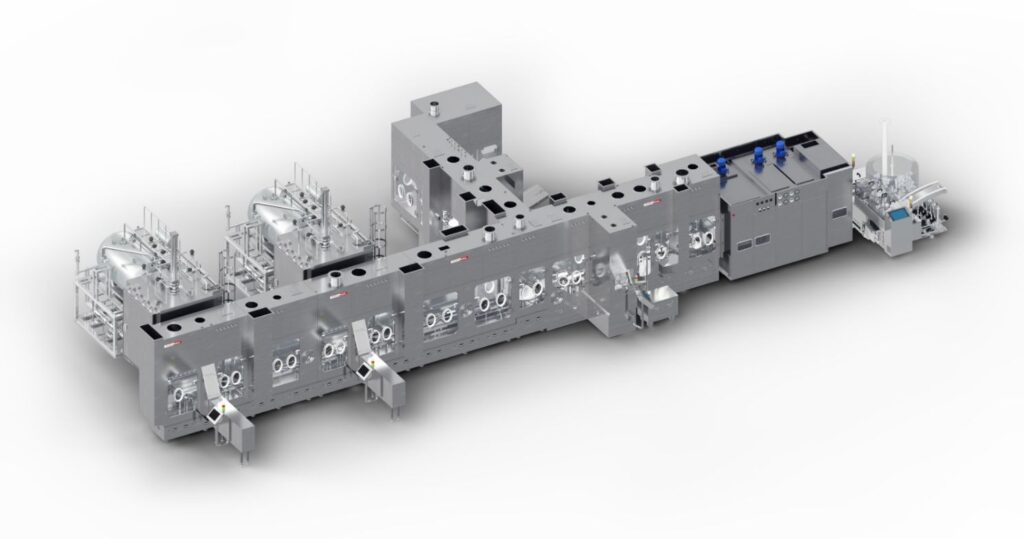

The ampoule filling line consists of a ACX Rotary Washing machine, SZA strerilisation tunnel and AGF Filling and Sealing Machine. Tofflon Filling Solutions offers cutting-edge technology compliant with FDA and GMP standards, ensuring safety and efficiency in pharmaceutical production.

Advanced Aseptic Processing Design

Advanced Aseptic Processing Design emphasises minimal human contamination in critical processes through systems integration with upstream tunnels and downstream equipment. This ensures a highly integrated, safely interlocked, and reliably recorded aseptic processing line, with a focus on RABS integration by design. It incorporates good practices in high-speed, large-scale, high-efficiency injectable manufacturing, reducing operator needs and operating costs. The servo motor control system ensures high automation, operational accuracy, and process reproducibility. Production batch reports are automatically generated, complying with GAMP5 and 21CFR PART 11, alongside critical parameter monitoring with record, print, and backup options. Additionally, fewer change parts and a tool-less design allow for quick changeovers.

Industry leading delivery times

Tofflons efficient manufacturing assures an industry leading delivery time for its products.

Yan Shen

Project Manager

“We will work with your team to choose the best products and specifications for your requirements. We can handle everything from the first phone call to installation.”

Call: + 33 6 31 55 95 79

Email: yan.shen@sofinn.com

Ampoule Filling & Sealing Machines

The Tofflon AGF Filling and Sealing Machine offers advanced features for optimal performance, including ceramic or stainless steel piston pump filling options. Driven by a precise servo motor, it incorporates nitrogen gas flushing before and after filling to ensure product integrity. Additionally, the machine is safeguarded by LAF and RABS protection systems, enhancing both safety and reliability.

| Model | AGF6 | AGF8 | AGF10 | AGF12 | DAGF12 | AGF16 |

|---|---|---|---|---|---|---|

| Ampoule Specification | 1ml-20ml | 1ml-20ml | 1ml-20ml | 1ml-10ml | 1ml-20ml | 1ml-10ml |

| Product Speed | 260 apm (2ml) | 360 apm (2ml) | 400 apm (2ml) | 500 apm (2ml) | 500 apm (2ml) | 600 apm (2ml) |

| Filling Accuracy | +/- 1% | +/- 1% | +/- 1% | +/- 1% | +/- 1% | +/- 1% |

| Broken Rate | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| Qualified Rate | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% |

| 0.05Mpa Gas Consumption | 0.3m3/h | 0.35m3/h | 0.4m3/h | 0.5m3/h | 0.5m3/h | 0.8m3/h |

| 0.4Mpa Oxygen Conspumtiom | ≤0.75m3/h | ≤1m3/h | ≤1.2m3/h | ≤1.5m3/h | ≤1.5m3/h | ≤1.5m3/h |

| Power | 5Kw | 5.5Kw | 6Kw | 6.5Kw | 6.5Kw | 7Kw |

| Weight | 2,700kg | 2,700kg | 2,700kg | 2,700kg | 3,000kg | 3,000kg |

| Dimensions (LxWXH) mm | 3400x1600x2600 | 3400x1600x2600 | 3400x1600x2600 | 3400x1600x2600 | 4070x1710x2600 | 4070x1710x2600 |

SZA Sterilisation Tunnel

The Tofflon SZA Sterilization Tunnel is engineered for high performance and safety. It features negative pressure sealing for HEPA filters, and its interior is made of stainless steel to mitigate the risk of oxidation. Advanced functions like automatic air balance and door position control, which can be set to manual or automatic, further enhance its operational efficiency and reliability.

| Model | SZA620-F | SZA620-F |

|---|---|---|

| Ampoule Specification | 1ml-20ml | 1ml-20ml |

| Belt Width | 600mm | 600mm |

| Product Speed | 750 apm (2ml) | 750 apm (2ml) |

| Broken Rate | ≤0.2% | ≤0.2% |

| Qualified Rate | ≥99.9% | ≥99.8% |

| Cooling Type | Air Cooling: Room Temperature | Air Cooling: Room Temperature |

| Air Consumptiom | 3,000-3,500m3/h | 1,000-1,300m3/h |

| Water Consumption | N/A | 0.6-0.9 m3/h |

| Power | 54Kw | 54Kw |

| Weight | 3,500 Kg | 3,500 Kg |

| Dimensions (LxWxH) mm | 4400x1550x2300 | 4400x1550x2300 |

Washing Mashine

The Tofflon ACX Rotary Washing Machine offers a compact yet flexible layout tailored for high-efficiency operations. It features an in-feed conveyor with a double design to prevent cross-contamination, ultrasonic washing, and alternant washing capabilities using water and compressed air. The machine’s gripper turns in situ, eliminating forwards-backward movement. Constructed with a hard aluminum-alloy big rotary drum and an integrated internal gear, the design enhances both reliability and precision. The machine is driven by a service motor for optimal performance.

| Model | ACX60 | ACX80 | ACX100 | ACX120 | ACX160 |

|---|---|---|---|---|---|

| Ampoule Specifications | 1ml-20ml | 1ml-20ml | 1ml-20ml | 1ml-20ml | 1ml-10ml |

| Product Speed | 300 apm (2ml) | 400 apm (2ml) | 500 apm (2ml) | 600 apm (2ml) | 700 apm (2ml) |

| Broken Rate | ≤0.2% | ≤0.2% | ≤0.2% | ≤0.2% | ≤0.2% |

| Qualified Rate | ≥99.9% | ≥99.9% | ≥99.9% | ≥99.9% | ≥99.9% |

| Compressed Air | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Air Consumption | 30m3/h | 35m3/h | 40m3/h | 50m3/h | 60m3/h |

| WFI Pressure | 0.3-0.4Mpa | 0.3-0.4Mpa | 0.3-0.4Mpa | 0.3-0.4Mpa | 0.3-0.4Mpa |

| WFI Consumption | 0.3 m3/h | 0.35 m3/h | 0.4 m3/h | 0.5 m3/h | 0.6 m3/h |

| Vapor Exhaust | 200m3/h | 250m3/h | 300m3/h | 350m3/h | 400m3/h |

| Power | 11Kw | 11Kw | 11Kw | 11Kw | 11Kw |

| Weight | 2,500 Kg | 2,500 Kg | 3,000 Kg | 3,000 Kg | 3,000 Kg |

| Dimensions (LxWxH) mm | 2330x2330x1360 | 2330x2330x1360 | 2330x2330x1360 | 2330x2330x1360 | 2330x2330x1360 |