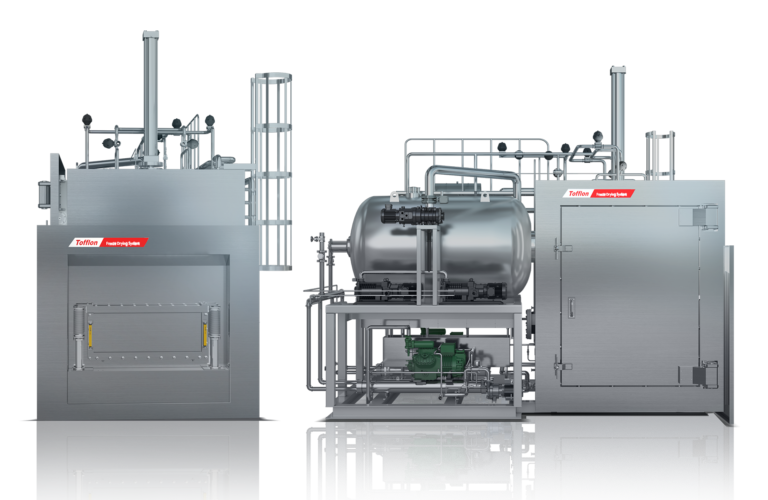

Le confinement est l’encapsulation de matériaux dangereux. L’échappement de substances dangereuses du lieu de travail (protection de l’opérateur) ou la contamination d’un produit par des impuretés dans l’environnement (protection du produit) doivent être évités dans de nombreuses applications différentes, allant de la production d’API à la production de pâtes pour batteries de voiture.

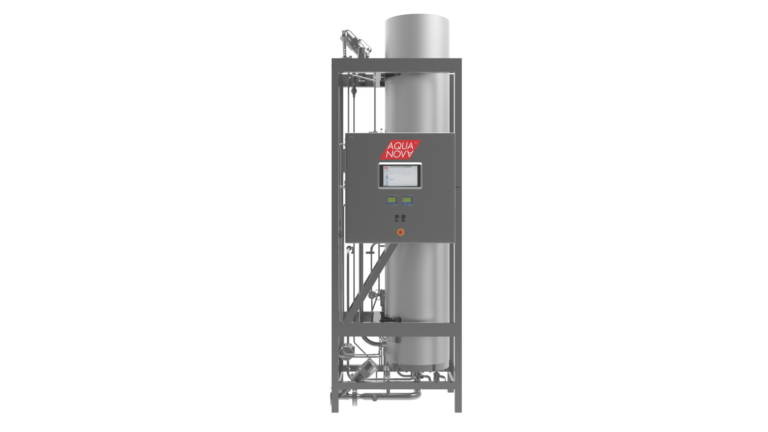

Aqua-Nova COMBI unit – Two in One

WFI and Pure Steam: two similar and yet different fluids

Simultaneous production is possible thanks to the unique Aqua-Nova technology. Here’s how!

Following strong interest